I agree, the Mini requires a ton of attention. Meanwhile, my associates who went with other brands have zero complaints.

I’ve printed lots of things on this machine. At first it worked fine. But the deterioration is ridiculous, it’s like trying to keep a Yugo running. A low-quality Yugo.

I’ve had to replace the nozzle fan twice. Then pay a third time for the new, larger, improved fan. This one didn’t bother me too much, but it just adds to the frustration.

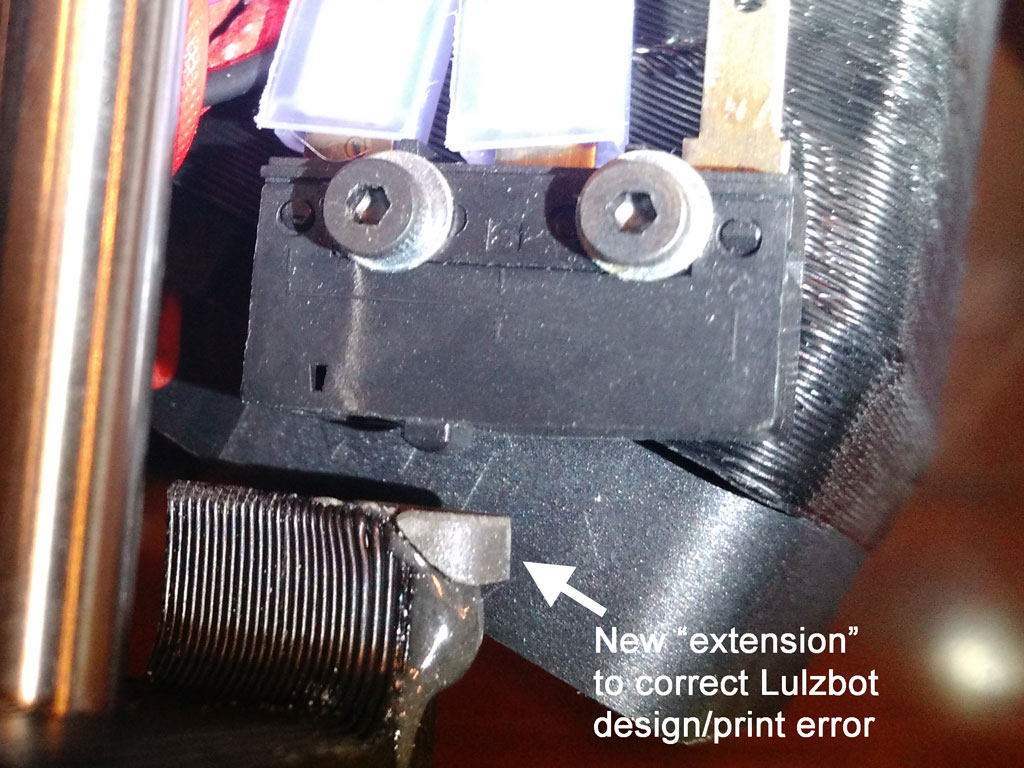

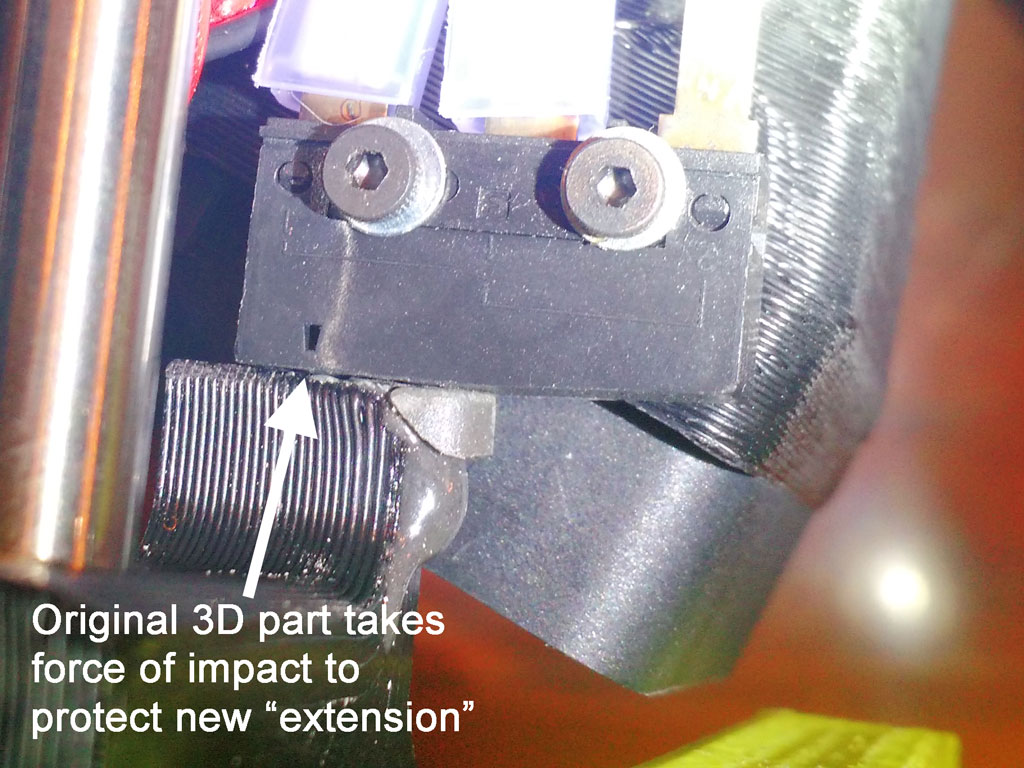

One of the 3D printed stainless shaft mounts CAME with a crack in it. I just found a second crack, in a second mount. My guess is that the screws were tightened too much at the factory. Maybe some higher-stress parts shouldn’t be 3D printed?

The Z axis offset seems to move around all the time, unpredictably. I’m constantly having to adjust it, sometimes by whole millimeters (!!!), to get the first layer to print properly.

I’ve had to replace the print bed due to the original one delaminating. Lulzbot sold me a replacement, without mentioning that the new one ALSO needed their upgraded heater - so once the new bed arrived I couldn’t install it until I ordered (and paid for) the heater too - even more expense and delay.

A while back the printhead started “dribbling” at the start of each print, when the extruder reverses the 30mm it backs out during cleaning and auto-leveling. Now it’s so bad that we sit at the start of each print with the tweezers trying to grab the giant glob that forms as the head slowly lowers to begin the print. Needless to say, this ruins a lot of prints.

I’ve tried hard to be loyal to the brand, but today is the last straw. Once again, this Mini won’t print. My 16YO son, who is a world ranked FPV Drone pilot and one of just five pilots on TeamUSA (just got back from the World Championships in Shenzhen China), uses this Mini to print parts for his aircraft. He gave up on fighting it for the umpteeth time this morning, so I took over…

…and I can’t get it to print even simple PLA. It extrudes just fine above the print bed, but when it tries to print it globs all over the nozzle instead of laying down a line. I figured it was the Z axis offset (again), so I played with that. I even used feeler gauges to confirm I was getting the changes I intended. No improvement. If I go high enough I don’t get any “squish” and the extruded filament just drags around. I can go too low and block the nozzle. In between, at the “proper” adjustment, it can sometimes start to adhere properly but then stops and just forms a huge glob on the nozzle which prevents any further success.

I’ve tried a range of print bed temperatures. I’ve tried different spools of PLA in case one got “contaminated” (humidity?). I’ve tried flipping to the pure glass side of the new bed. I’ve made certain the nozzle is shiny clean. I’ve adjusted the vertical screw shafts (again!) to insure the nozzle is a consistent height across the Y axis.

Nothing helps. Meanwhile, my son reports that several of his pilot friends worldwide are having excellent success with some $200 unit that’s available today. He’s shown me some prints that look better than ANYTHING we’ve ever gotten out of this Mini, even when it was new.

When we first looked at buying a 3D printer for home, I did a ton of research. The Mini stood out for its excellent customer support, and I liked the strong user community and forums in case I ever needed them. At $1200 it was far more expensive than many alternatives but we needed a TOOL, not a hobby, so I justified the expense.

But after today, I’ve had it. I think this Mini is going in the junk heap and we’re going to get one of those $200 units. I’ve wasted at least $200 of my time, again, just today, on trying to get this thing to work. I’m an Engineer (hence my username), so I’m not exactly stupid on technical matters, but the Lulzbot Mini has just wasted too much of our time. I understand the difference between a tool and a hobby, and while I respect those for whom 3D printing is a hobby, I need a reliable tool. I spent a lot of extra money specifically to avoid doing exactly what I’ve just wasted half my day doing - and it’s not the first time. But it will probably be the last.

In the past when folks have asked my recommendation for a 3D printer I’ve pointed them to the Mini. That ends today. And my son, with his worldwide community of FPV pilots, will be doing the same. I’m very sad to say that but frankly we feel betrayed and out far more money than was necessary.