This is an extension of the Linear Z rail project for the Ao-10x series printers, but I figure it will be large enough in terms of posts and pictures that it warrants its own thread.

I have been chasing the perfect Z axis configuration for a while now, and I’ve realized that for my purposes at any rate, the ACME rod that comes with the printer is not going to be adequate. I can get “pretty good” prints most of the time with it, and the occasional really good print, but an unsupported and in my case bent rod is not going to allow for that perfectly accurate print I want every time. I was hoping the linear rail alone would be enough to provide the necessary support, but it seems that is not the case. To that end I have acquired a pair of inexpensive Chinese 300mm SFU1605 ballscrews, with pillow blocks. Total cost for the ballscrews and the blocks was about $120 total for both sides.

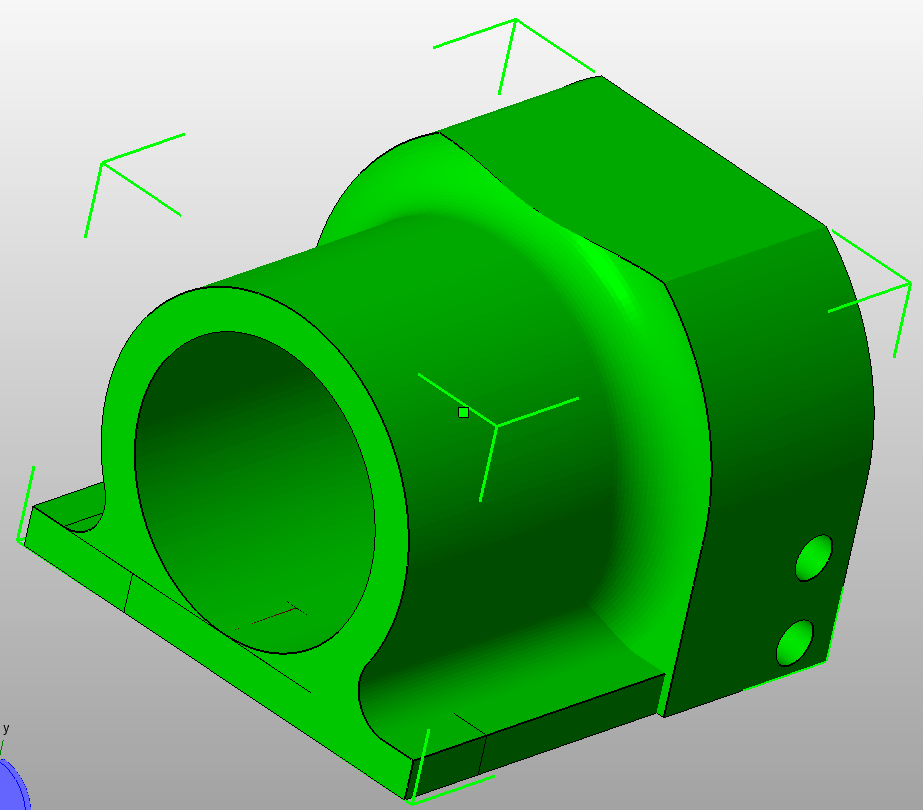

The ballscrew itself is very straight compared with the acme rod, it’s stronger, and it seems to be much smoother in movement, and most importantly, no side to side deflection on thread movement. It is quite a bit bigger though, so the existing X ends are going to need a significant rework to fit everything.

My present theory is to do a solid direct mounting and eliminate the decouple spring entirely, since the ballscrew has no deflection to compensate for. Here are some pictures of the current mock up. (That short section of Linear rail is the same dimensions as the full length ones on the real rails.)

The backplate installed presently is one of the thinner original prototype backplates from the Linear Rail project. I’m probably going to have to go with that thickness to make things fit.

For the lower X end clamp, I am considering something somewhat radical. Instead of a removable ballscrew mount “spring” section (or solid mount in this case) why not incorporate the mount directly into the X end clamp? I’d have to replace the clamp nuts with heat set inserts, and I would lose a bit of ease of part removal for troubleshooting, but it would be much easier to make that whole section fit. More importantly, it would also give me a better platform for the next stage project, Linear X rails, when I get that far.

I also know i’ll have a clearance issue with the Z endstop target that i’ll have to deal with eventually. It will probably get incorporated into the bearing mount somehow.

At any rate, that’s what it is shaping up to look like for now. I’m waiting on the top bearing mount and another short linear rail section before I draw the actual ballscrew coupler up.

Anyone have any ideas I can poach or suggestions?

Here we go again!