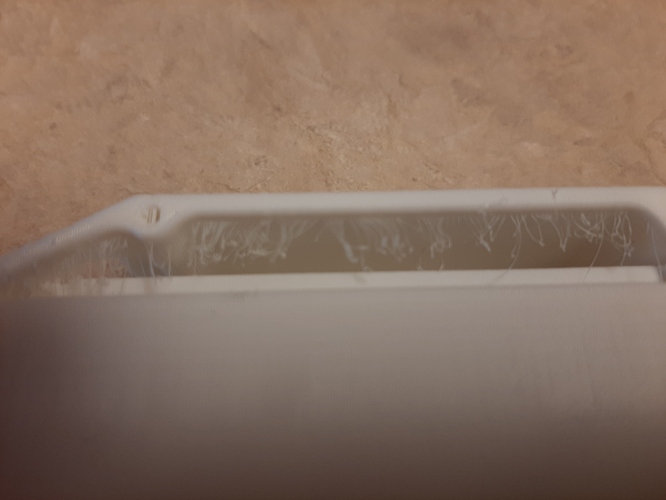

Using PLA at 220C There a lot of hair like strands on my printed part.

Any advice on what I’m doing wrong?

Can you provide a little more detail? Which printer & print head are you using? Which PLA are you using? Which slicer software are you using?

Good morning Tim,

This is done on my new Workhorse I just received a few days ago. Serial # 1958

Standard tool head and nozzle that came with the new machine.

PolyLite PLA True White

Lulzbot Cura 3.20 that came with the machine.

I used the same profile that was used in creating the test piece for PLA. I did not make any changes.

The support structure was really hard to remove and broke out some detail because of a thin wall on my part.

The hair like strings I assume are when it retracts and rapids but not enough experience to really know.

Unrelated to this but because I was having issues I pushed the auto calibrate button on the Workhouse control. That was a big mistake.

The X axis rapided to the X- side and hit a hard stop. Then it rapided straight down in the Z axis until the nozzle was about 5mm below the top of the bed off to the side by the cleaning pad. Then it rapided X plus until it hit the side of the bed. I turned the machine off at that point and restarted it before it broke something. I had to reset the Z offset back to -00.20 then everything seems to be working again OK.

What is the auto calibrate used for. That probably should be a protected action from noobies like me from breaking the machine.

I really appreciate your help. I know I am the red headed stepchild right now but I will figure this out.

I am a mold maker by trade and own my own mold shop. I have run CNC equipment since 1980 including machining centers, CNC lathes and Wire EDM machines.

I would very interested in any sources of information you might steer me onto as well. I am on several Facebook pages and looking for help on YouTube videos.

Thanks again,

Jim Wright

Aero-Mold Inc.

When it comes to the auto-leveling or auto-calibrate functions the WorkHorse is EXTREMELY sensitive to having a VERY clean nozzle. If you have any leftover plastic that’s dripped from the nozzle and cooled the electrical connection can’t be made between the nozzle and the opposite metal parts. Before you auto-level or auto-calibrate make sure you warm up your nozzle to a temp where cleaning it with scotchbrite is easy, but not so warm as to allow any filament in the nozzle to leak out or drip.

Then buff that nozzle like there’s no tomorrow before you auto anything.

Then to be safe, buff that nozzle a second time.

Again, I think the key is to warm nozzle up before really cleaning it, then clean it twice as long as you think you need to when you first start using the machine.

There needs to be zero filament anywhere on the nozzle.

A quick scotchbrite rub on all the metal contact parts won’t hurt either.

Make sure to blow off everything you’ve scrubbed with the scotchbrite too before you hit the auto anything.

Hope that helps.

I’ve watched in horror as that nozzle slams down on leveling disks and pushes the whole bed down almost a half-inch.

This had nothing to do with the nozzle. The x axis crashed in the x axis before it ever even came down and when it did come down it missed the whole table.

Unrelated to this but because I was having issues I pushed the auto calibrate button on the Workhouse control. That was a big mistake.

The X axis rapided to the X- side and hit a hard stop. Then it rapided straight down in the Z axis until the nozzle was about 5mm below the top of the bed off to the side by the cleaning pad. Then it rapided X plus until it hit the side of the bed. I turned the machine off at that point and restarted it before it broke something. I had to reset the Z offset back to -00.20 then everything seems to be working again OK.

What is the auto calibrate used for. That probably should be a protected action from noobies like me from breaking the machine.

Hi Jim,

I’ve got a few meetings this afternoon … but when I break free I’ll post the settings I use for PolyLite PLA with my Workhorse and we can compare settings.

Thanks, I appreciate it.

Jim

Probably the most significant change I made for PolyLite PLA on the Workhorse was to raise the print temp to 230°C

I use:

Print temp: 230°C (225°C is ok for "initial printing temp and final printing temp).

Bed temp: 55°C or 50°C … but use the same temp for initial layer and all layers. Normally it may want to print initial layer at one temp, then the remaining layers at a slightly cooler temp. I have … a few times … encountered situations where the part broke free of the bed when doing this. When I use the same temp for all layers I no longer have the issue. Apparently allowing the build plate to cool off 5°C was just enough contraction on the filament to weaken the adhesion. These days I flip the bed to the glass side and use MagiGoo.

Retraction distance: 1mm

Maximum Retraction Count: 5

Minimum Extrusion Distance Window: 2mm

These settings avoid having the same short segment of filament roll through the hobb gear over and over … chewing up the filament. This is only an issue on jobs that have lots of retractions in a very tight area. It causes Cura to skip excess retractions until it gets on to some fresh filament that isn’t chewed up.

Print speed: 40

Infill speed: 40

Wall speed: 35mm

Initial layer speed: 15mm

In the Travel section I sometimes enabled “Combing Mode”. This causes the nozzle to travel along the part instead of moving directly to the next area that needs extruding. It increases the travel time, but when using filaments that “ooze” and may result in stringing, the filament oozes onto the inner walls or infill so that you don’t have stringing. This usually is not necessary with PollyLite PLA as it wont string much (if any) at 230°C with 1mm retraction.

In the Travel section I normally leave “Z Hop When Retracted” off. But when I do turn it on, I usually set it to “Z Hop Only Over Printed Parts”. This is because sometimes Z-hopping leaves a tiny nub where it pulls up (like a tiny “Hershey’s Kiss”).

Other things:

Linear Advance: The printer runs Marlin 2.x firmware and Linear Advance is already enabled… but the “K” value is set to 0.0 (effectively this means the linear advance wont make any modification to the flow rate).

As the print head changes speed, the extruder also changes speed. But since filament is in a state of “goo” when melted, there’s a little bit of a delay. Linear Advance allows the Marlin firmware to respond by altering extrusion speeds in advance of acceleration changes so that you get smooth extrusion.

When I ran the Linear Advance test on my Workhorse using PolyLite PLA, I found the best setting on my particular printer was K=0.13. When I ran the same test on my Pro I found the best setting was K=0.12 (so very close).

You can set the K value by (using the control panel on the printer itself… not in Cura) navigate to “Configuration” -> “Advanced Settings” -> “Filament” -> “Advanced K” and then dial in the value you want (e.g. I set it to 0.13). After doing this, I think there’s another menu where you have to ‘Save’ the setting … otherwise it will lose the setting when you power off the printer.

I am using your suggestions and printing a small part to see what happens. I’ll let you know.

Thanks so much.

Jim

Fantastic!

BTW, to work out the optimal temperature for printing, I printed the material to create a “temperature tower”. You can think of a temperature tower as a model of a high-rise building with many “floors”. You print each “floor” of the building at a different temperature … then inspect the model to decide which one did the best.

These things typically have overhangs … bridges … and other features designed to be difficult to print so that they expose weaknesses in materials at different temperature or print settings.

If you search for a “temperature tower” you’ll find loads of these things. The one I used was here:

But when you get this, the “files” folder has lots of temperature towers … I used the one named “SmartTemperatureTower_PLA_Plus_195-235.stl”

This prints the bottom layer at 235 and drops by 5° for each “floor” of the tower.

Load the model into Cura but set the temperature to 235°C. You’ll use a Cura “extension” to change the temperature as it prints.

Once you load the model, “prepare” it (slice it). By default, Cura LulzBot Edition has a setting called “Slice automatically” enabled. This means anytime you change any parameter it re-slices the model for printing. I typically change several things so I disable “automatic” slicing and just click the “prepare” button when I’m ready to slice.

With the model loaded and set to print at the base temperature (for this model that’s 235°C) … “as if” you want the whole thing printed at that temperature, you’ll then use a Cura “extension” to tweak it.

- In Cura, from the main menu, click “Extensions” -> “Post Processing” -> “Modify G-code”

This opens a new window where you can select and configure extensions.

In the extension window, pick the pull-down for “Add a script”. The script you want to add is named “Tweak at Z or Layer” (although I find in different versions of the software the name of this script varies a little… but the name will basically convey the idea that you can change settings when you reach a layer number … or a heigh above the build plate.")

When you select the script, you’ll see values populate like this:

Notice that I’ve set the “Trigger” to the value “Layer No.” (it will trigger at a specificities layer number vs. a heigh (in mm) above build plate). To know which layer number … I put Cura in “Layer view” and then use the slider to find the layer where the first “floor” of the high-rise temperature tower is completed and it is about to start the next “floor”. In my case… that was layer #45.

There are many things you can change at a layer or height… but what we want to change is the temperature. So tick the box marked “Tweak Extruder 1 Temp” which will expose one more row asking for the new value (Extruder 1 Temp) and since you were previously at 235°C… set the new value to 230°C.

When the printer reaches layer #45 … it will drop the temp to 230°C.

Using the “Layer View” … scan through the layers to find the layer number for the 3rd floor, 4th floor, 5th floor, etc. and note those layer numbers.

Back in “Extensions” -> “Post Processing” -> “Modify G-code” select “Add a script” again.

Repeat… but this time add the layer number for the next “floor” of the high-rise and set the temperature to 225°C.

Repeat again and again for each new “floor”.

Print the part and monitor the printer as you do to make sure the temps are changing as expected.

Honestly… you’ll probably want to abort the part before you even make it to 200°C because you’ll see the quality diminish as the temperature drops.

Inspect the part for the layer with the best qualities. The temp tower has over-hangs of different angles, “bridging” over gaps, and it even prints a tiny cone which you can try to break off with your finger to test layer bonding strength.

BTW these scripts are active for your session in Cura. This means even if you clear the build plate and load a new part… it’s still going to do temperature changes at these layers heights. You an either go back into “Extensions” -> “Post Processing” -> “Modify G-code” and delete the scripts or quite and re-start Cura (it wont save these if you quit & restart).

Anytime I print a new type of filament that I haven’t used before, I tend to do one of these temperature towers to work out the optimal printing temperature. You’ll notice you can change lots of other things… fan speed, flow rate, etc. so you can use it to evaluate all sorts of things.

While PLA tends to be one of the easier things to print, I’ve encountered materials that are very sensitive to things such as printing speed and fan speed. For example, PETG doesn’t like high fan speeds (fan speeds should be either completely off for a glossy finish… or in the 10-15% speed range for a matte finish). Also the quality of “bridging” over gaps will change based on fan speeds. Some materials are sensitive to print speeds (e.g. with respect to stringiness, etc.).

Basically when I get a new filament type, I play with it.

One more thing… I’ve learned over time that even when using the same type of filament from the same vendor … but just different colors … can change print settings.

E.g. I’m printing PETG from IC3D. When I print in colors (such as “blue”) and find the best settings… bu then change to “black” filament, suddenly the filament is a bit more stringy and maybe I need to drop the print temp by 5°C.

For some reasons “white” filament (from nearly any vendor or any type of filament) tends to be fussy. (maybe the titanium dioxide additive used to make it “white” is to blame??) So I uses these test to play with the filament to try to dial in the optimal print settings.

You don’t know how much I appreciate your help. I didn’t specify a color when I ordered the PLA. When there is more stock available I’ll order some different colors to play with. I am printing a part for a customer and it’s coming out so much better now.

Thanks again.

Jim