I found when I set with the 8mm spacer that I downloaded, it was too loose, and I had some slipping. So I tried 8mm to the outsides of the washers - better, but still not great. So I just tightened it down another mm or so from there and it seems to be working. I was using a reconditioned tool head while the original head was out for repairs (I suppose it’s possible the springs are worn or ??). I was printing with PLA filament (which I believe has been around for a while - donated to the school, but have had no problems with it). I suspect the ideal tension may vary with the type of filament in use; I just haven’t used enough kinds to judge this yet

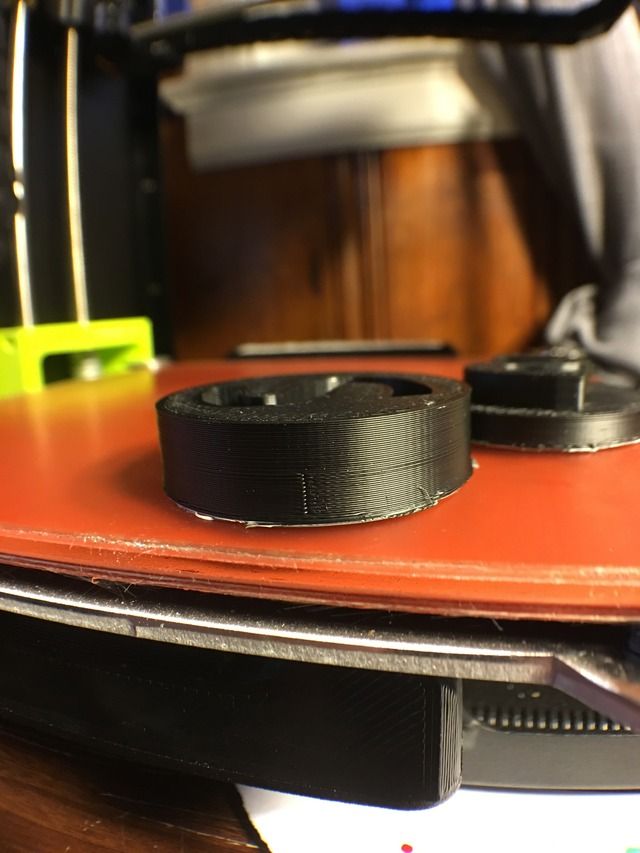

I also printed up the tool for setting the idler.

My mini was still adjusted to where it came from the factory, and I hadn’t had any issues with it.

I found that the tool fit from outer face to outer face of the washers, i.e., the compressed spring plus two washer thicknesses.

I will likely keep using this setting until I have a reason to suspect it. You may also notice that the tool cutouts fit over the washer OD perfectly.

I think there is a setting that is just right, and either side of that may cause problems.

Too loose, and it slips.

Too tight and it crunches your filament.

Just right, and it works like it should.

YMMV.

exactly how i have mine set and i havent seen any issues as of yet as far as the hobbed gear slipping. before i was able to guess how tight it needed to be just to get it to feed properly for long enough to get a print out of the machine to make that little tool , i was having a HELL of a time getting that tensioner setting just right

im super glad i ordered one of these just for this procedure. the calipers are a bit too awkward to get in there and be accurate i found.

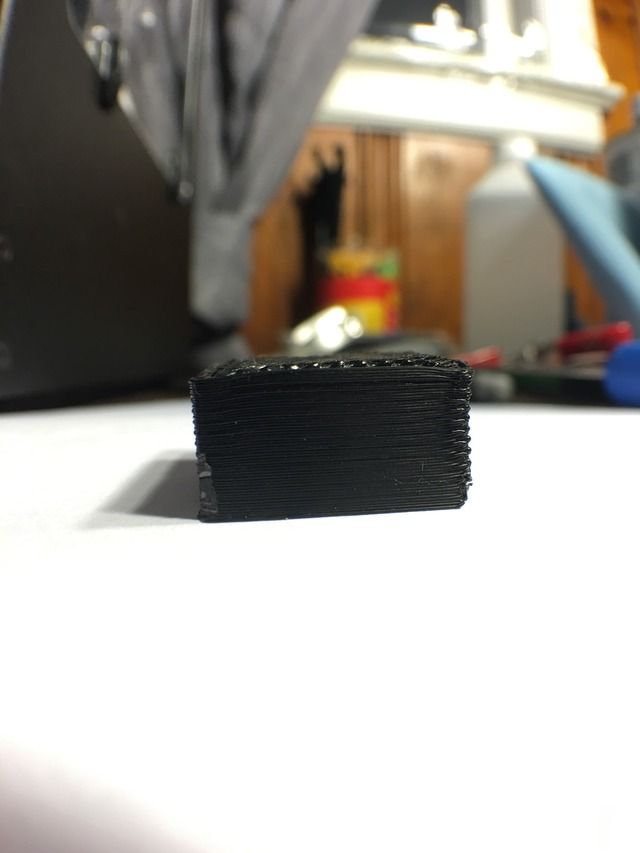

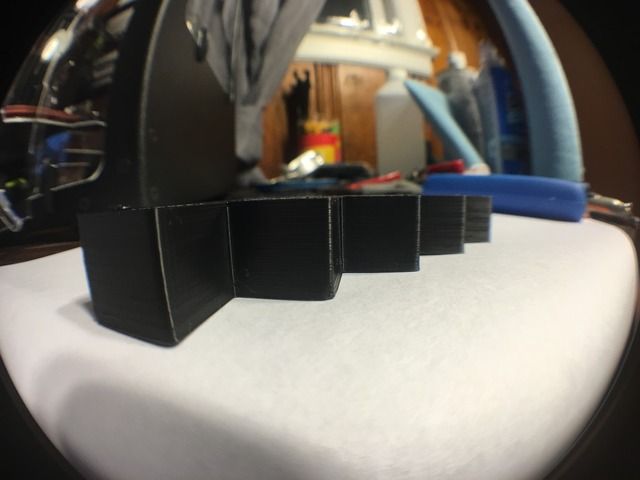

so after getting my esteps with the slower manual extrusion i printed out some more cubes.

.6mm manual extrusion width

.1 layer height

got the 4 walls of .63/.65/.65/.65

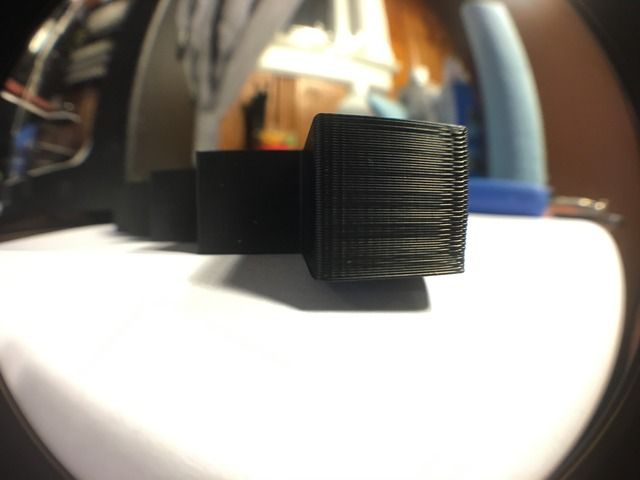

took those numbers, did the math and it came out to be .93 on the extrusion multiplier. so did 93% of current esteps (821) and got 763.5 printed another cube and it was all pretty much dead nuts .60 wall thickness.

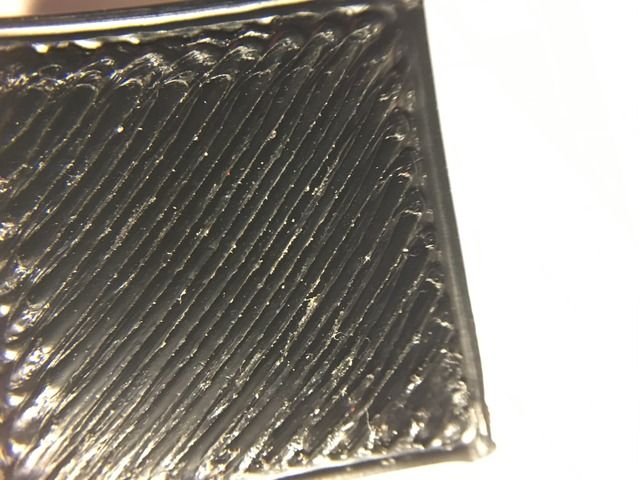

then went on a printed another of of the 5mm calibration cubes at a 95 percent infill and .1 layer height and pics are below.

esteps @ 763.5

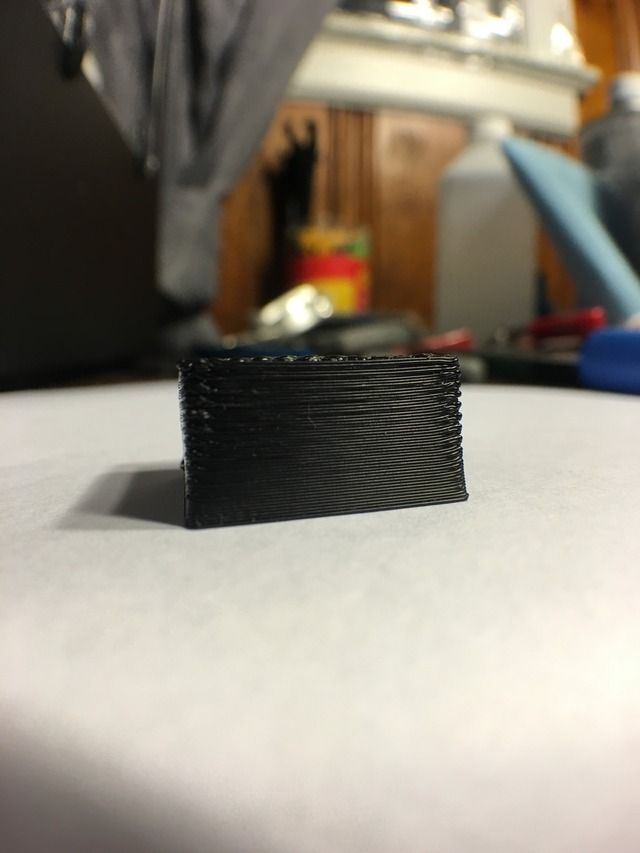

im not exactly sure what to look for with this test to be honest other then according to the wiki there should be just the slightest of gaps between the lines with a 95 percent infill. i will say that the lower estep value seems to have much sharper corners.

these cube steps are nice to see since you print it at 250% size as per the wiki, but to do an entire steps print would be a few hours so tomorrow im going to do a few of the solid 20mm test cubes and see what that does since those wont take so long to do, and i want to be able to see how the top layers come out.

That is looking quite a bit crisper than your earlier photos. Looks like a bit of effort on this is really paying off for you.

What you’re looking for is for there to be a very small open space between the lines in the infill, and just enough extrusion to not have gaps for solid layers. For that 5mm step pyramid, the best place to watch is when the outside steps start getting their solid layers. You can see solid and infill at the same time. At 0.2mm, when scaled up, that’s about an hour of printing to get there. Using more solid top layers will help there. Maybe not scaling it up so much as well.

Remember to give it a layer or two for the change to take effect. Your pictures look like you’re going in the right direction. Maybe try some other small test prints to make sure everything else looks good.

Is there a better calibration piece that I can try to show this quicker? I’m going to scale it down to 150-200 percent a and print another one. Maybe even tell it to print more top layers so it gets to the first set of steps top layers quicker.

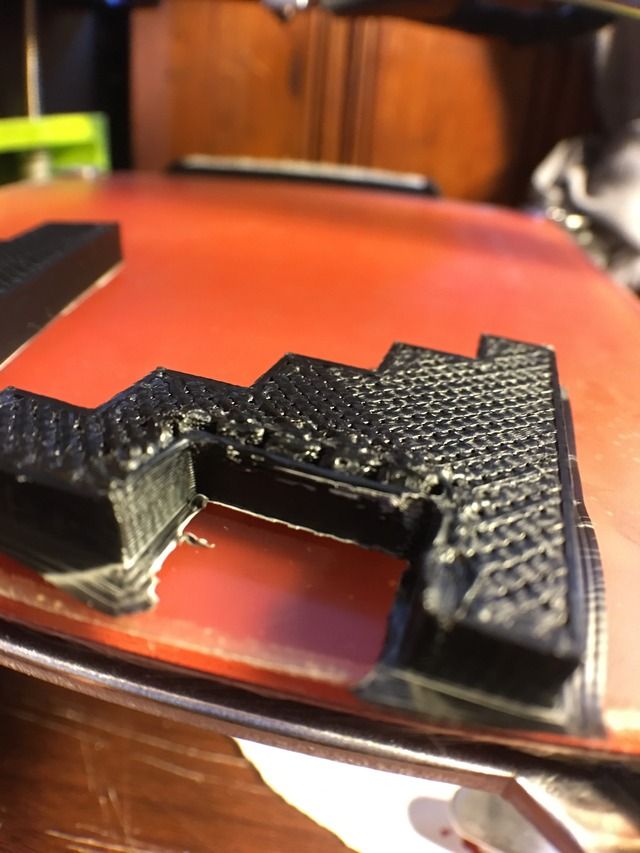

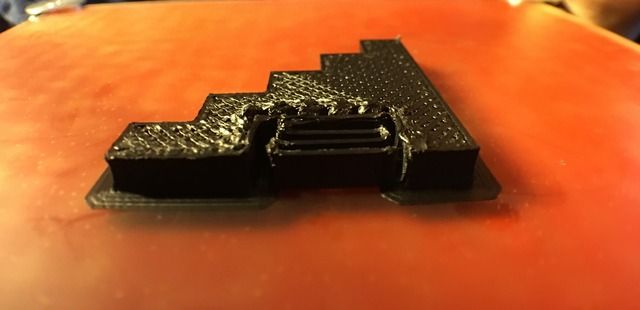

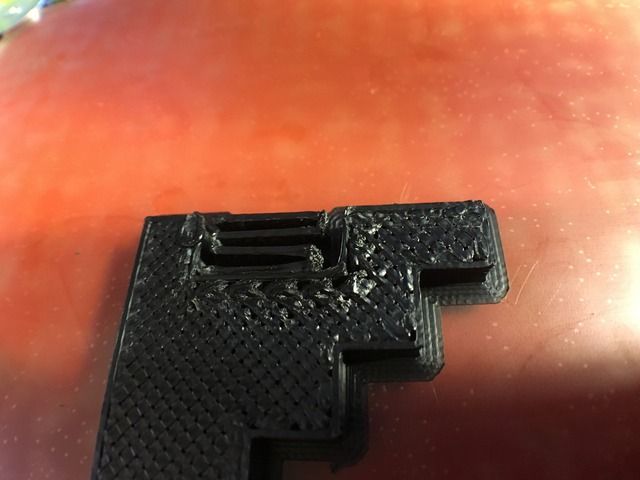

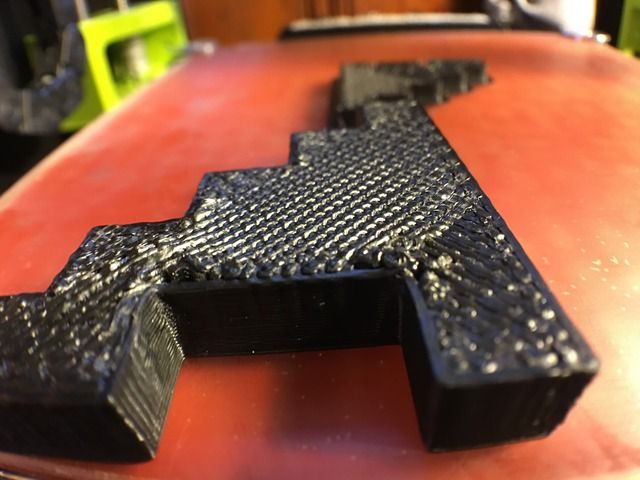

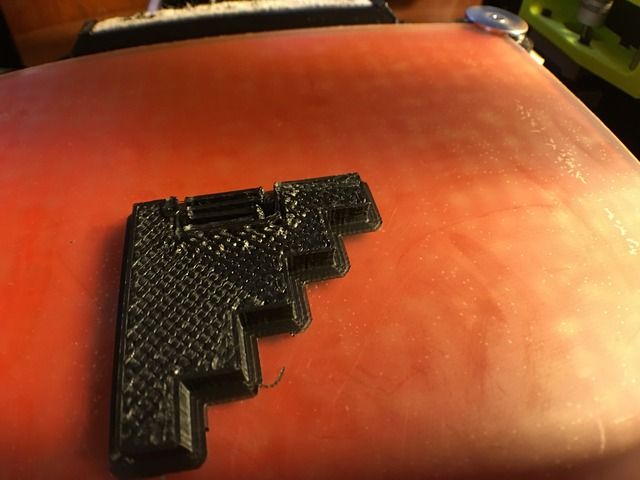

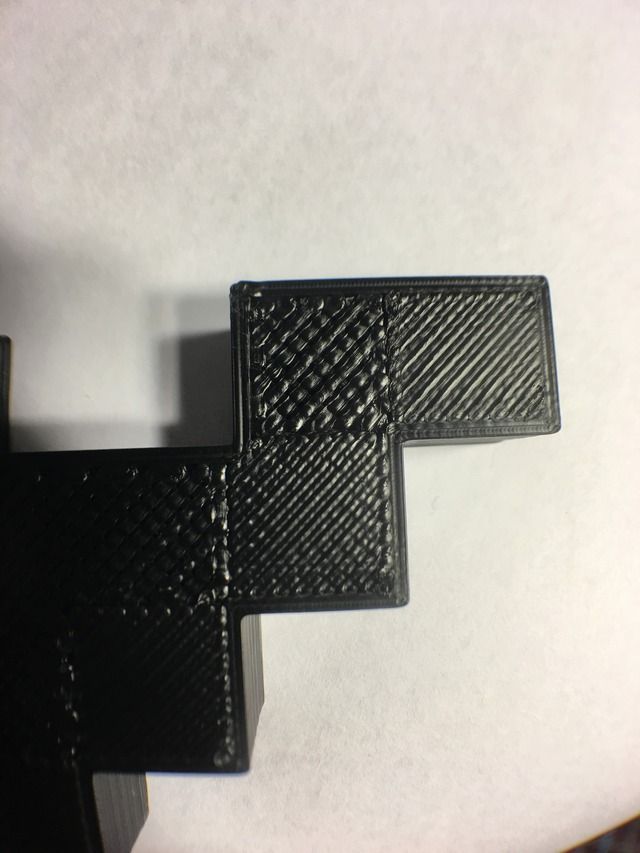

attempted to do the cube steps at just 150 percent scale and i ran into this issue. same thing happened when i tried it at 200 percent scale as well.

First question. on the infill layers it seems as if the nozzle is dragging on the last extruded layer, what could be the cause of that problem? overextrusion? retraction?

printed a test fit part and it doesnt fit, not even close actually. although i do think the top layer looks pretty good. at least much better then my top layers were when i started out this calibration process. measuring the center of that S the plug is 5.23mm and the piece it should pop into measures 5.03mm

extrusion width set on auto.

multiplier at 1

layer height at .2

shells at 2

The nozzle dragging across the top layer is usually over extrusion. That could also explain the parts not fitting together. Over extrusion makes holes smaller and outside dimensions larger. So that seems to make sense based on the pictures. On the step part, it seems pretty good overall. The issue you note around the cutout is new to me though.

What slicer are you using, and did you change any other settings? Perhaps we can narrow it down.

I’m using Simplify 3D.

Out of curiosity. What do peoples esteps normally end up at?

What I find odd, is if the single wall cube I print has the proper wall thickness. Why does it seem to over extrude with other prints?

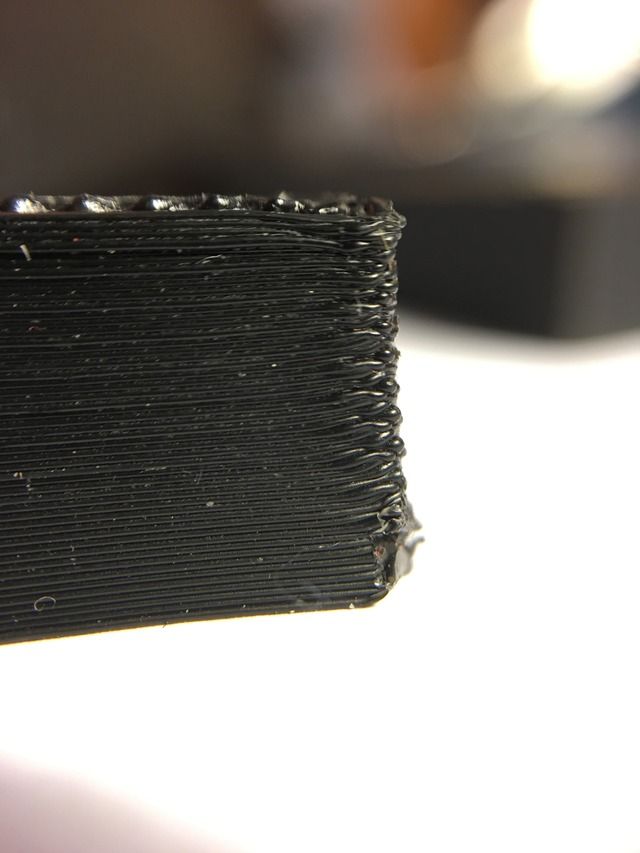

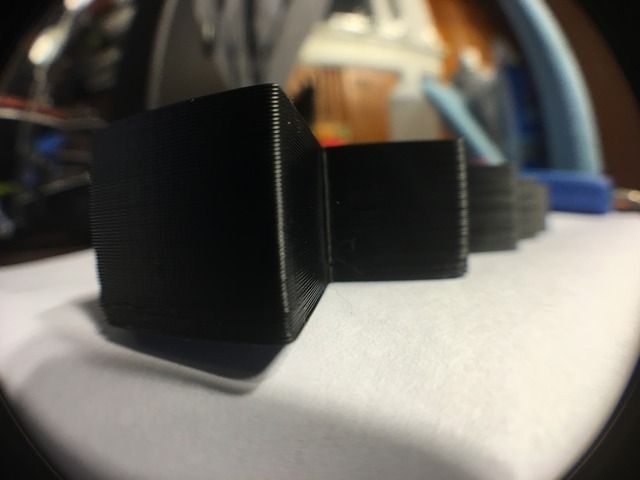

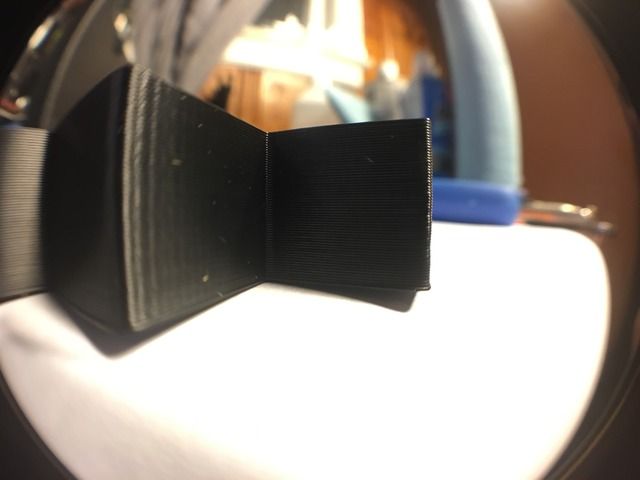

so, i stumbled upon a PDF file on here that had a bunch of Simplify3d profiles to start off with on a Mini. i added in the values in that it had for ABS and i came out with these prints. needless to say, im quite happy, a few more tweaks (with the help of some pros on this board) and i think i will be right on the money!

only issue i see, using my olloclip macro, is

-the infill doesnt quite touch the outter shells

-the corners, some, look a little jagged, droopy

calibration cube, measured 19.99-20.02mm depending on where you measure it, so not bad there. height, which i think should be 10mm, ends up at 10.75mm, so im not sure what thats all about. (overextrusion?)

and heres the steps that ive been doing in the previous posts, cutting off right as they get to the first set of top layers

its odd some of the corners on the steps calibration look nice and sharp, others look droopy as you can see.

It looks like you are getting a bit of lifting on some of the corners, I’d bump the bed temperature up a bit possibly. What layer height do you have set? the initial laer you want a 0.40ish layer, and then a 0.35mm layer for subsequent layers for starting, then adjust from there.

It looks to me like you are underextruding a bit, check the diameter of your filliament with calipers and adjust the value in Cura as needed to match. Also turn off the fan entirely for ABS if you have it on at all.

primary layer height is set at .20mm, first layer height is set to 150% of that (so .30)

the diameter of the filament i have checked, its set at 2.74 currently.

now, just out of curiosity here. it looks to me as if its underextruding as well, i assume that from the gaps im seeing between the outter shells and the infill. but other things ive printed, such as a male/female plug before, dont fit together easily (as id assume they would if i was underextruding)

fan is not on at all. bed temp as 100

Have you tried slowing down your print speed by say 30%? Give it a shot, print a test piece.

That should reduce the overshoot loops at the corner. Once you get it perfect, then you can try for faster, although faster may never be better. You have to decide which is more appealing for the job…

It looks like you’re getting very close. What fill percent are you using in the last couple prints?

originally, if you look at the first pics i posted. i was running at a speed that was in the default setting on Simplify3D for the Mini, which was 3600mm/m. after doing some digging around and finding a nice PDF that someone put together with recommended settings the mini with S3D i turned the speed down to 3000mm/m.

another thing i noticed with my start gcode that i have in S3D, there wasnt a G21 command at the beginning. would that be a source of any issues?

another question. when doing the estep calibration, telling the printer to extrude 100mm of filament and seeing just how much it does extrude, should the values be spot on each and every time? i feel like i have a good number for the esteps and then itll underextrude by a few MM, next pass its spot on, pass after that it may overextrude a few MM. is that normal?

so after playing with the estep calibration again due to underextruding. i tuned it in and printed another cube. im assuming here, that this is overextruding, so i took a little video since im new at this and i just want to make sure for future reference. it seems as if the next layers are almost ‘pushing’ the layers below it around, thats why im assuming its overextruding here.

Yeah, you are overextruding there.

Cool. If I know what I’m looking at and what’s happening, I’ll be better suited to fix it whilst it’s happening next time.