Thanks for the suggestion, I’ve added it to the OP

That looks much less annoying to use than the one I have now. I ordered the Pa-09 to try first since it does the smaller wires that I need for my LED strip rebuild, will probably bring in a Pad-11 if that works well. I need to figure out which is the smaller of the plates available for it though.

Well I use a PAD-10 handle with the PAD-11S which is the Small pins die, but the P-09 is for the micro open barrel connectors if you are using those. It takes a little skill to use to crimp the pins right. Which I do not have.

Ok you convinced me. I grabbed one of them as well. I’m horrible at crimping pins, but I blame at least part of that on my current crimp tool, which is terrible. I also grabbed one of these: https://www.amazon.com/gp/product/B06X95Q5D9/ref=oh_aui_detailpage_o01_s00?ie=UTF8&psc=1 which was reccommended on the same page, and only $15, for crimping round barrel connectors.

One of my near future plans is redoing the entire wire loom for my main Taz to eliminate all the extensions that currently exist in the X-Z cable chain, and to add in all the Taz 6 wiring changes except the leveling (ferrules, additional grounding, etc. ) So that may also come in handy.

Well I currently have it printing out a tree frog, and just need to tweak the Z-Offset a little more then it looks to be working OK!

Had to put an ~2.3 MM spacer between the BL touch and the mount to get my BL touch smart to not push the bed down during homing operation. Otherwise I seem to have it working.

Well I currently have it printing out a tree frog, and just need to tweak the Z-Offset a little more then it looks to be working OK!

Had to put an ~2.3 MM spacer between the BL touch and the mount to get my BL touch smart to not push the bed down during homing operation. Otherwise I seem to have it working.

I currently use a 1mm spacer, originally I had a 2.1 mm spacer but that pushed the offset limits in the firmware. I’ve updated the file on Thingiverse to be 1.1mm longer.

My current offset is -0.3 nowhere near the -2.0 limit.

i will have to print the new part and see how it works. I think my BL touch smart is shorter than yours.

My current offset is -0.3 nowhere near the -2.0 limit.

i will have to print the new part and see how it works. I think my BL touch smart is shorter than yours.

That’s actually a good point, the BLTouch can be adjusted to engage closer or further. From the factory mine was adjusted all the way down (so it reacts sooner) and I just didn’t change it. There’s a hex screw on the top, tighten it to make it engage sooner and loosen it to make it engage later.

Since this is very important I’ve added it the the OP now, even though the rest of Z calibration instructions are on pause.

Updated OP.

After many print issues I figured out that the motors weren’t really capable of making frequent small back and forth changes. Motions like these are a necessity for printing using auto leveling. The motors would make noise, try to move, but not actually move when tiny motions were needed. This only happened in certain scenarios and would create a big mess when it did happen so I decided to upgrade the fairly weak motors to the nicer motors used on the taz 6. So far the issues seem to have been resolved.

limit the maz sp

Updated OP.After many print issues I figured out that the motors weren’t really capable of making frequent small back and forth changes. Motions like these are a necessity for printing using auto leveling. The motors would make noise, try to move, but not actually move when tiny motions were needed. This only happened in certain scenarios and would create a big mess when it did happen so I decided to upgrade the fairly weak motors to the nicer motors used on the taz 6. So far the issues seem to have been resolved.

Glad to say I did not have this issue yet, but I do set default max step rates for the motors. The leveling has worked so far perfectly for the about 100 prints I have done so far.

I would love to do this mod on my Taz 6 - while the Lulzbot auto leveling is good, keeping the nozzle clean enough to give accurate touches is a PITA.

I’ve followed along in the instructions - only question I have is how the firmware mods would be different for the 6 vs the 5 since the 6 already has auto leveling?

Any help or advice would be greatly appreciated!

Thanks,

john

You should just need to turn off the 4 point leveling that lulzbot uses while turning on the things turned on in the OP, can’t be sure though. Make sure in lulzbot config file you select the taz 6 rather than taz 5 too. You also won’t need my replacement bed corner but I’m not sure if my extruder mount will work on the Taz 6.

You’ll have to do some research and dig through the firmware to get it working right. If you get it to work you should document the steps and make another thread for the community!

If you end up stuck and have a specific question I’ll try to help. I’m still a novice and was only able to do this thanks to the awesome firmware that’s super easy to customize thanks to marcio from Lulzbot.

I’d rather just edit my current Taz 6 fw - since I’ve already made some minor changes of my own - thermocouple temp control, extruder based on the itworks.com design using the Titan Aero etc, etc

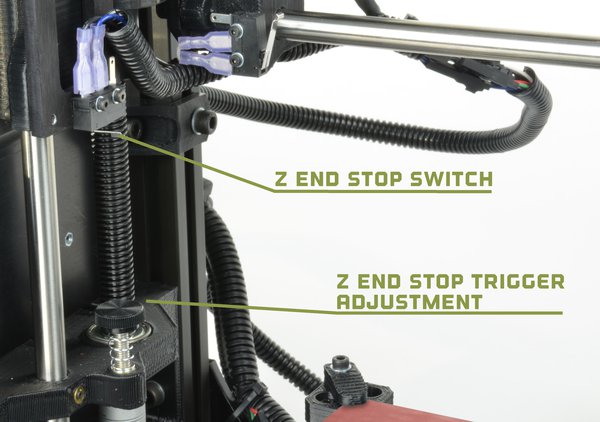

Does the Taz 5 have the same z min switch as the 6 - looks like an elevator push button?

Obviously I have to change the coordinates of the touch points and tell the probe when to deploy etc…

-john

I’d rather just edit my current Taz 6 fw - since I’ve already made some minor changes of my own - thermocouple temp control, extruder based on the itworks.com design using the Titan Aero etc, etc

Does the Taz 5 have the same z min switch as the 6 - looks like an elevator push button?

Obviously I have to change the coordinates of the touch points and tell the probe when to deploy etc…

-john

Ok - so totally different - I have no idea how to edit the fw to change the way the Taz 6 does it’s thing - would I just change the locations of the touch points? The 6 uses the nozzle itself to press the z min end stop switch which is adjacent to the back left side of the bed… then it would have to switch and use the touch sensor to probe the bed.

-john

It should no longer use the built-in z endstop and only use the bltouch. I should have said that in my last post.

What tells the probe to deploy? I’m just trying to conceptualize everything I will need too hunt down and change…

-john

This link from the OP should help. It depends on what version firmware you’re using. The latest lulzbot dev version is the easiest to work on and I highly recommend porting your current changes over if you’re going to take on this project.

Basically there are some bltouch specific settings and maybe a servo setting that does some behind the scenes magic that makes it very simple to enable.

I’m thinking it would be easier to use your modded dev version (this is the rar file at the bottom of the OP correct?) and just add my Taz 6 mods - i.e. turning off the z switch as mentioned previously, thermocouple temp control etc, and changing the printer name and extruder name to Taz 6 etc - the extruder name doesn’t really matter - never messed with that before as I’m using the itworks.com version of the titan aero extruder for the Taz.

Thanks so much for the help - I know just enough about the firmware to make me a danger to myself…

-john

There’s a lulzbot config file where you define which printer and extruder you have and when you compile it auto fills the many custom values for the taz 6. It’s wonderful.

I’ve been using a newer version than the one in the OP; I should look for any more updates and test that. If all’s good I will update the OP, hopefully I can do that this week.