I have been experimenting with changing the filament path of my TAZ 6. I’ve been getting snapped filaments from the amount of torque and force brittle filaments like laybrick, laywood, polywood get when they go through the filament tube into the idler.

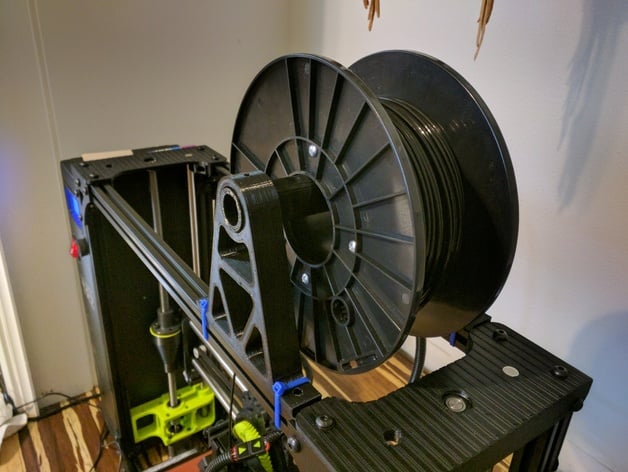

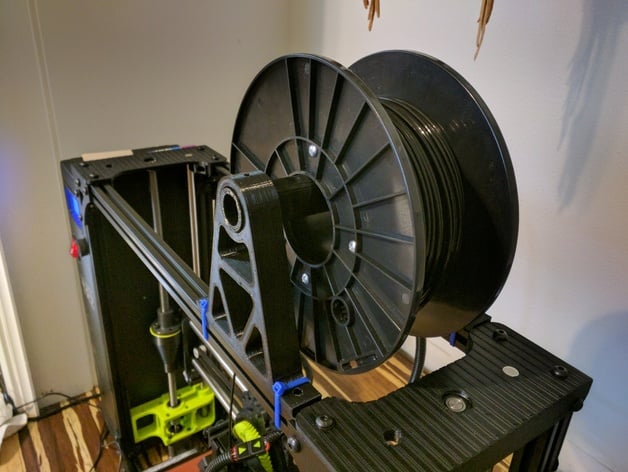

This is the best solution I have found so far – mount the filament reel on TOP of the machine, not the side. This eliminates the need for a filament guide tube, and the friction that the tube has. ( same problem delta printers have with bowden tubes )

These filament holders are easy to print, use standard 3/4" PVC pipe has the spool holder, and so the job very well. So far, they have fit all the spools I have purchased from Lulzbot, MakerGeeks, HatchBox, and others. When you put a PVC tube in them, they support themselves, but I chose to ziptie mine to the machine and 3D print the tube.

http://www.thingiverse.com/thing:1424791

I have been using them for printing PLA for a while, and I have them sitting on my Taz 6 right now. It Works has a set they use also since I showed him how well they work.

Plus I had printed him a set to try.

I guess I should thank Bill for coming up with them.

I had a similar problem with my TAZ 5 filament breakage but for a different reason. I was printing with Matterhackers PLA and was having frequent breaks, particularly near the end of the spool. Initially I thought that there was problem with the filament, and contacted Matterhackers, who very nicely sent me 2 spools of PLA gratis. Turns out the problem was temperature. It must be warm where Matterhackers lives, but in December-January here in New England it gets cooold, particularly in our house, where the daytime temps are in the low 60’s, and nighttime at 55 or so. (My wife says we don"t heat the place!) What was happening was that as the filament cooled, it would break, sometime at several locations in the feed tube. So I made a mount similar to yours, which was an improvement, but the filament

still broke if we were away and the house temps were set in the low 50’s. The solution was to mount a small floodlight (25 watts or so) directed horizontally at the filament spool centerline about 6" to the left of the single spool while printing. (I haven’t graduated to dual filaments yet.) I haven’t had a break since, and now that it is summer I don’t need to use it.

pete

Good point Pete… however the house here is always in the mid-70’s ( sometimes high 70’s ) and eventually I will be putting the printing area of the TAZ 6 inside a cabinet of some sort to maintain heat stability. For now, mounting the spools on top of the TAZ printer seems to have solved my filament feed / snapping issues.

My next trick will be to design a new head to go into that universal mount. The TAZ printing head has a lot of mass, and I’d like to experiment with a setup that uses a compact stepper + direct drive … similar to what some delta bots use.