Hello, everyone, I need your helps with my mini2 machine. it starts wiping the muzzle and then the first corner touches very hardly (even making sound ) and then goes back to, making level X, after 3 times it gives me the error of bad leveling and then probing failed screen comes . please I need your suggestion.

thank you

Check the level of your X axis. I’ve noticed when my TAZ 6 axis is out of level I get the exact symptoms you described. A quick and descent method to do this is bring the print head down close to the bed on the left side, slide a piece of paper under the nozzle until you fill slight resistance on the paper while sliding it around. Raise the print head, say about 10mm high, move it over to the right side. Now you should go down 10mm and fill the same amount of resistance that you had on the left. If you do your bed is level already. If you don’t you’ll need to turn the Z rods in the appropriate direction needed. Turn off power and do it by hand, using the LCD panel or software interface you will move both z rods at the same time being counter productive  I’m assuming the mini has 2 z rods like the larger TAZ 6.

I’m assuming the mini has 2 z rods like the larger TAZ 6.

And of course, make sure your nozzle is clean and don’t use a wire brush with power on else you’ll be replacing a micro fuse.

The printers use continuity to detect the corners of the bed. The metal tip of the extruder touches the metal washers in each corner – which completes the circuit.

The nozzle needs to be clean when it touches… anything on the nozzle will act as an insulator. Sometimes it can visually look clean, but there’s enough of thin build-up to throw off the accuracy of the touch. I use a brass wire brush to scrub the tip of the nozzle once it is hot (if it’s cold, the filament doesn’t scrub away so easily).

BE CAREFUL here… because there are wires connected to the thermistor and heating cartridge that you do NOT want to let the wire brush touch. Only scrub the tip of the nozzle. (If you want to scrub more of it… heat up the hot-end then switch off the power before scrubbing).

If you own a multi-meter (if you don’t … it’s probably a good investment for anyone who owns a 3D printer) switch it to report Ohms (resistance) and use the probes to touch the two corner bed washers. You should read 1Ω of resistance or less for any pair of washers you test. If any washer reads higher … check to make sure the washer is snugged down. (I had one particular corner that often failed the test … and discovered it was loose).

The washers on the bed are only half of the circuit. The print-head is the other half.

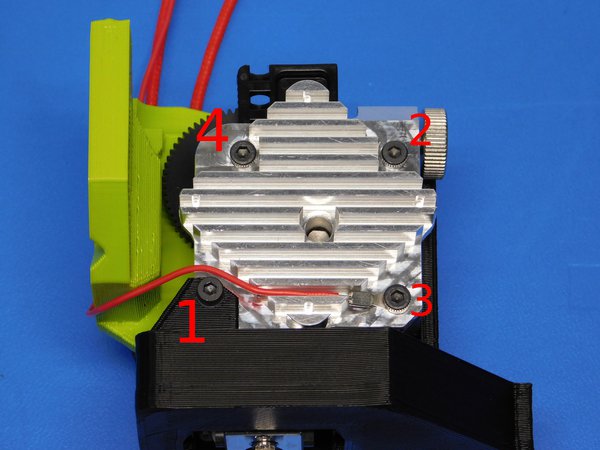

On the print head there are four screws around the heat sink. ONE of the screws has a red wire attached to it.

You can find the diagrams on this page:

https://ohai.lulzbot.com/project/lulzbot-mini-2-aerostruder-assembly-and-packaging/mini-2/

But this picture probably shows it best (in section 10 of that page). This is the zero-sense wire:

That’s the wire (attached to the screw marked ‘3’) that completes the circuit for probing the bed corners.

Touch one probe of the multi-meter to that wire. Touch the other probe to the tip of the nozzle. It should read less than 1Ω.

If your printer is reading high when you test this and still under warranty, contact LulzBot support. (I had to clean mine … the steps are a bit involved and … somewhat intermediate to advanced… so I don’t necessarily recommend anyone attempt to disassemble, clean, and re-assemble their print-head on their own unless they’re comfortable with the process.)

I would also suggest cleaning the contact washers on the print bed. This was driving me nuts as to why I could not complete the auto level. I finally wiped all the contacts with alcohol and that fixed my problem. I had a thin layer of hairspray that was preventing the contact.

I tried what you cleaning nuzzle but not worked and I do not have multi-meter so I couldn’t try that, and still problem same

Owning and maintaining a 3D printer requires a few simple tools with a Multimeter being one of those tools. You can get one for less than the price of a spool of filament. For example, https://www.amazon.com/Etekcity-Multimeter-MSR-R500-Electronic-Multimeters/dp/B01N9QW620.

You need to clean the nozzle while it is hot with a non-conducting material like a Scotch-Brite pad. These come in a variety of grades and this would be a good start, https://www.amazon.com/StewMac-Scotch-Brite-Different-Polishing-Refinishing/dp/B07DLDP6HS.

You need to clean the four corner washers. Start with some Isopropyl Alcohol (70% or 90%) which you can buy at any drug store and most grocery stores. Put some on a paper towel and wipe the corner washers. You can also lightly use the Scotch-Brite pad from above, or some fine grit (1000+) sandpaper, https://www.amazon.com/dp/B07K3RM6KW.

Buying all three of these items is still close to the price of one spool of filament, and will help keep your 3D printer running smoothly.