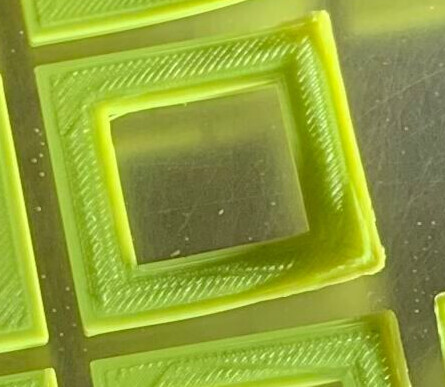

glass plate is new/fresh and cleaned thoroughly with alcohol. Adhesion is good across the whole plate for the first two layers then pealing begins on right side. Does this look like uneven build plate heat?? Printed a 1” cube positioned at plate center and the bottom right corner is warping up off the plate as well.

Your Z offset looks a little low, and/or there’s some overextrusion.

Is the skirt another part of your test print, or do you have the profile set to do so many excessive perimeters?

Can you do a few single-layer test squares and show the bottom and top?

The tests you suggested:

https://www.dropbox.com/scl/fo/7m5ts659nhxewlbrd610r/ALntVBJlts1oDm-cJVqvXwQ?rlkey=sapya7iw9rm6fhu8jagg9nuq4&dl=0

The mix of too close and too far here:

Makes me think you have a mechanical problem, like a loose toolhead, loose toolhead mount plate, worn linear bearing, or the bed washers are not consistent. With four points of measurement, there should be a simple slope problem with the mesh, so where you have inconsistent highs and lows so near, there’s more to it than just a dirty nozzle (although dirty nozzles are still the #1 cause.

What is the machine actually measuring? Post the result from

M420 V1

I had this issue with a stock TAZ 6. Most of the time with ABS. I put reflective foil under the heater, enclosed the printer with reflective insulation. It helped but the real improvement was adding a BL touch. I do use a brim on tall aspect prints but no problem with lifting anywhere on the table. Adding the Touch bracket also allowed another attachment to the tool carriage which removed all wiggle during the wipe. I do a100 point mesh and keep it unless I change something. Each print gets a 3point to tilt the entire mesh. I also run the Archim 2 board as is much faster and quiet. Hope that helps.

Thermal of my Mini2 build plate heater. indicates a variance of 14° over surface. Heater set at 65° but image indicates max is 44° (?!?)

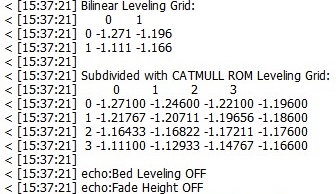

Checked for any looseness in and around print head but find nothing. Here are the M420 V1 reports…

Report before printing:

Report after printing started and bed leveled:

The leveling looks good.

Assuming your equipment is accurate, that measurement for a 65 degree setting is definitely off. Thermistor may be wrong or defective. If you let the temp settle for a few minutes, does it get any better?

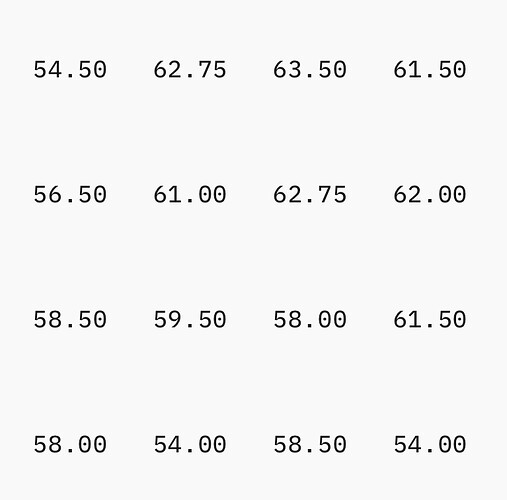

Borrowed an old Roybi point-n-shoot temperature reader and get very different readings from plate set at 65°

Mechanically, not sure what to do other than replace bushings and rods. Maybe Y axis first?

Speaking of thermistor, maybe do a PID Auto Tune on the bed?

https://teachingtechyt.github.io/calibration.html#pid