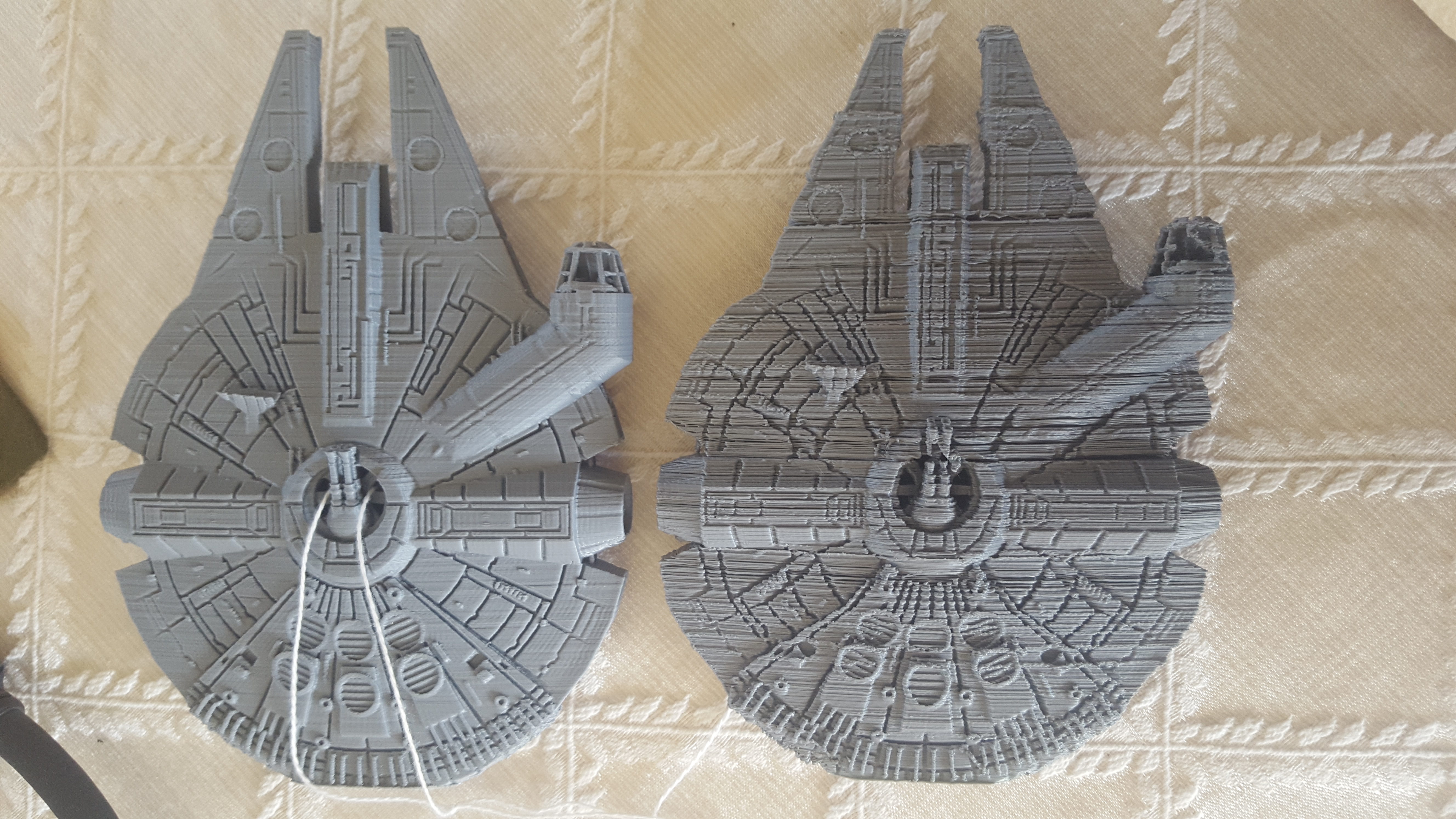

The left is a print I did a week ago and the right is this morning.

I used the exact same gcode with same filament. I think my extruder stepper might be dying but I wanted to ask here for advice before I got a new one.

Check your tension on the two thumb nuts for the extruder assembly. There should be 5mm between the washers, i.e., the spring should be compressed to 5mm long. They should also be even.

They may be backed off too far, causing your filament to slip.

You may also want to check your hobbed bolt, as it might be loaded up with plastic bits from slipping, causing it to slip even more.

I don’t think it could be the motor.

I tightened the thumb nuts and brushed out the hobbled bolt and its not any better.

What material are you using?

Neither one look that great. The one on the right looks worse, right off hand I would say you are over extruding. What material?

ABS

I checked the motor and both coils read 3 ohms. Didn’t do any current testing but I guess its fine. I should probably mention the problem started when I got a jam during a print. It kept going several hours like that. The shredded bits of filament filled up the mini blower fan on the extruder, but i cleaned that out. I broke the extruder down and took some pictures.

It looks like your nozzle may be damaged.

If you do a test extrusion from full Z height, how does the string look? If it isn’t round, that might be your issue.

It looks like you might have some lost steps or belt /pulley slippage in the x and / or y axis. Check your belts and pulley tightness along with the extrusion quality when you get it back together. Also check the tightness of the lead screw to motor couplers.

When you extrude into free air, the extruded plastic should drop straight down out of the nozzle. If it curls to the side or corkscrews as it exits the nozzle, you have a partial blockage in the nozzle.

Well I solved it. When I was repairing the wiring harness for the Y end-stops I accidentally unplugged the control box fan. Stepper drivers where overheating and I was loosing steps on every axis. The OHAI doesn’t mention where to plug this fan in. I guessed it had to go in fan 2 from the wiki page on the mini Rambo and found a reference to it further back in the forum. Lulzbot if you are reading this please add the control box fan connector to the mini OHAI.

Also when I was reviewing the OHAI I noticed they put a heat-sink on the Z-Axis driver chip, my Mini lacks this. How important is it and where can I get one? I find it interesting that this is the chip that has the heatsink because it behaved the worst when I didn’t have the case fan running. It is of course driving 2 steppers so I can see why it would need the extra help.