Eh Brew, lol…ya well, I gotta keep it clean on the public forum, especially since I’m trying to build a reputation here so as you can see, I kept my response pretty sterile. I’m pretty sure he get’s the point. If anyone downloads his link, please understand that I don’t endorse it at all, the CAD model looks WAYYYY off and out of proportion.

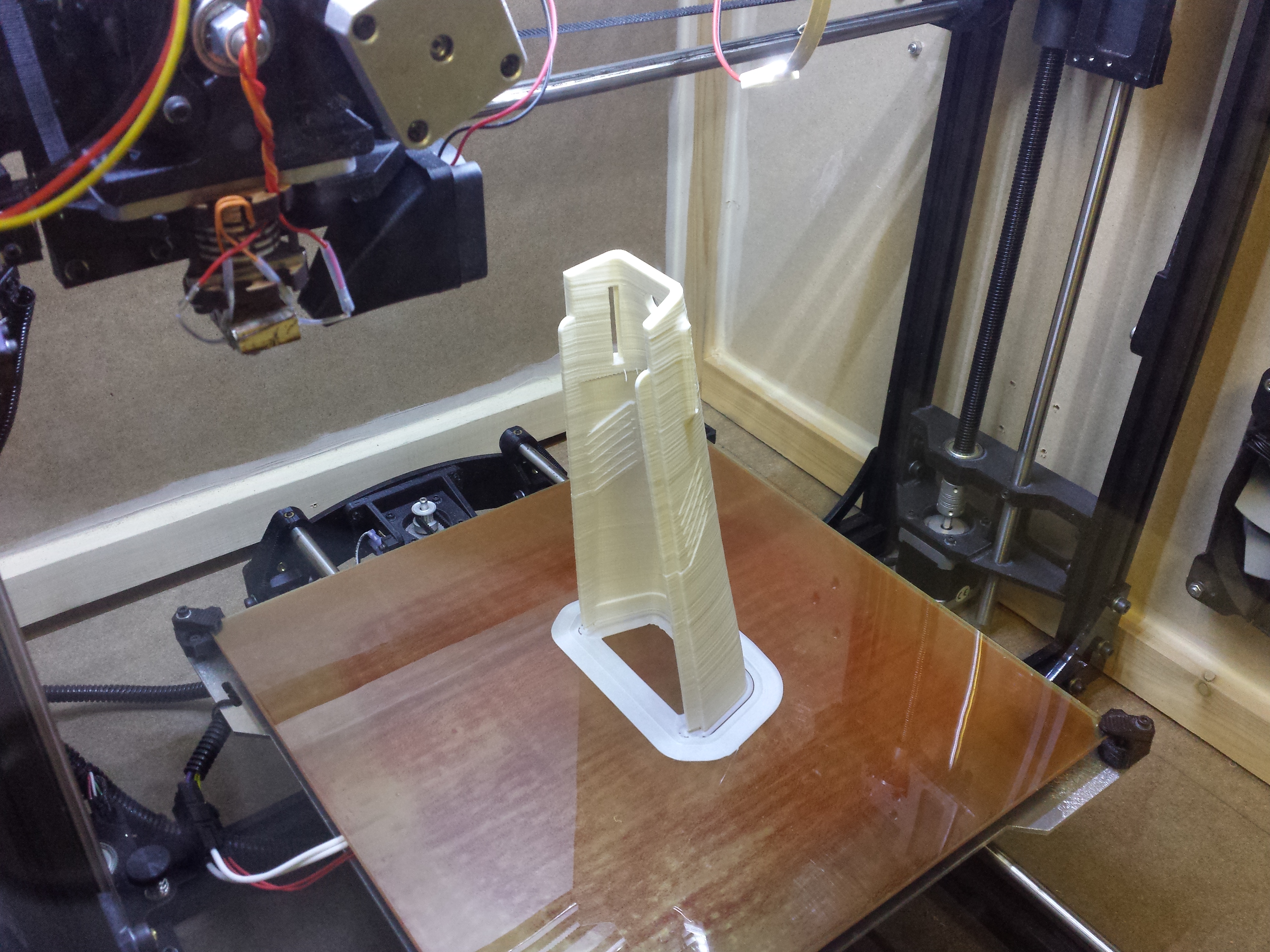

It took a month or two for me to really tweak the dimensions and parts for this “HOTBOX” design so there’s a lot more involved than just slapping together a few panels in CAD. *Sigh.

I’ll leave it at that.

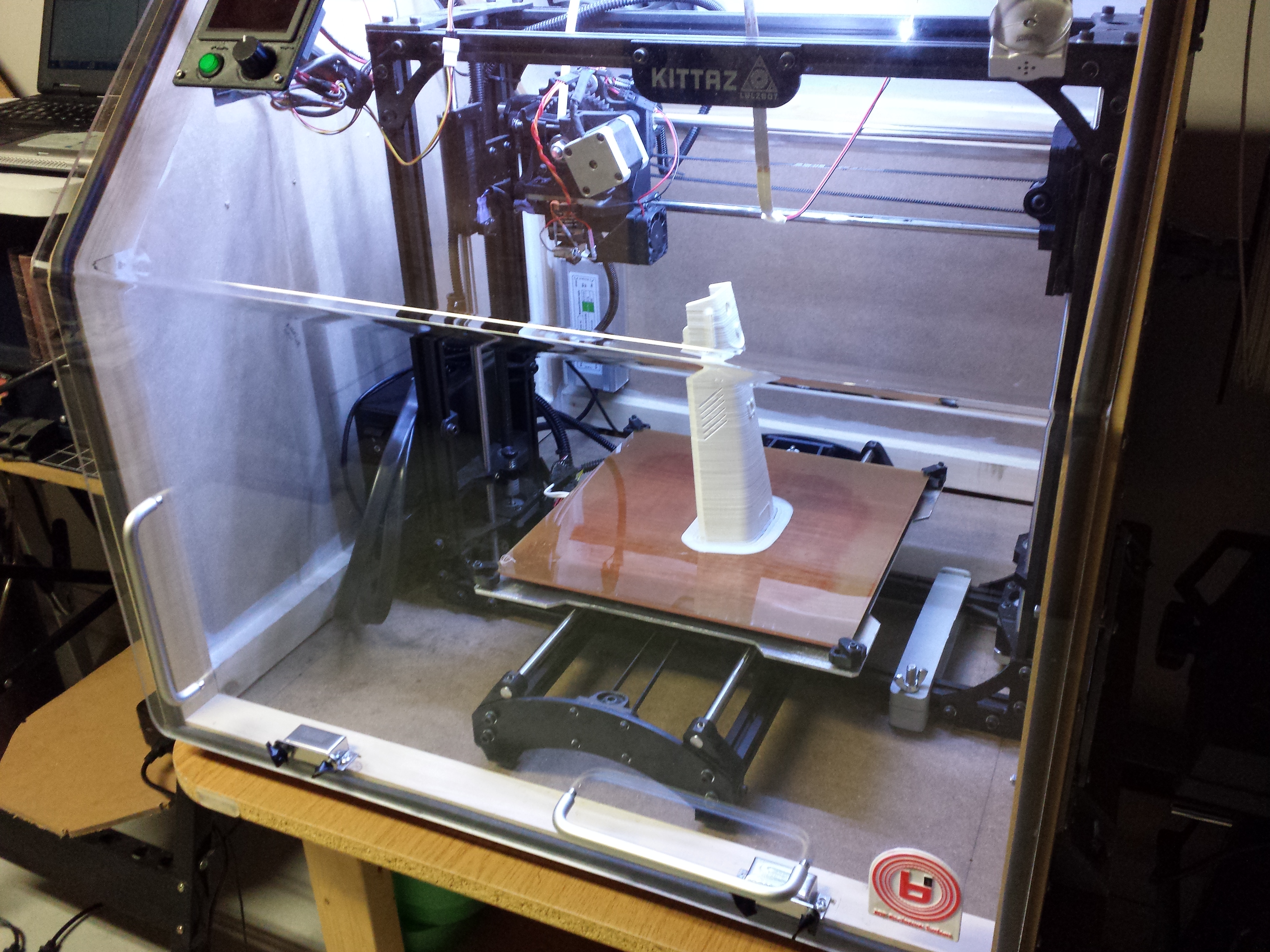

Ok awesome! if you can hold off for about a month or so, we’re looking to source in all the parts into a nice tidy package, all for around 200-230$US, +S&H. You’ll get the .stl files and build instructions also. I’ll be there to help you with any questions, but it’s pretty straight forward stuff, my instructions walk you through with tons of HD pictures and there’s plenty of room to put your own flavor into it also if you don’t want to follow the plans to the T.

so ya, basically for the acrylic panel, go to your local sign or plastic shop and ask them to cut you a 1/4" acrylic panel and bend it to the dimensions as per the instructions. Whole thing should cost you no more than about 50$.

Honestly, the look of the bent acrylic panel REALLY set’s it apart and gives it a quality look, all for little money so I’d really recommend sticking with the bent acrylic, but ofcourse, other options are possible. We’re casually looking into getting an aluminum version made that can be shipped as a full kit, unfortunately we’ll probably have to swap the bent acrylic for two flat pieces so it can be shipped as a flat pack to keep the shipping costs down. Dems are the breaks. We’ll see how it pans out though.

SEE, this is why these forums are soooooooooooooooooooooooooooo awesome. Love the idea about the air filter. For now we’ll probably keep things pretty low key and basic and just offer a standardized kits, just to keep the costs down and make things simplier on ourselves, but by all means, hack away and throw idea’s on here! We’re gonna build this thing together and make it the best it can be! Let us know what you find out!

Congrats dude and good luck!

Congrats dude and good luck!

a good FYI for would be kit owners…

a good FYI for would be kit owners…