I have a Taz Pro with a LulzBot TAZ Pro Dual Extruder tool head, which currently uses 2.85 nozzles and 2.85mm filament. Is it possible to just swap out with 1.75mm nozzles to use 1.75mm filament, or is there more to it than that?

How reliable does it need to be? Just swapping the nozzle leave the filament completely unconstrained in the heatbreak tube inside the meltzone. If you print fast and never have to retract, you might get away with it, but at how much of a pain it is to clear jams in the Aero (even moreso the aeros in the Dual Toolhead), I wouldn’t recommend it.

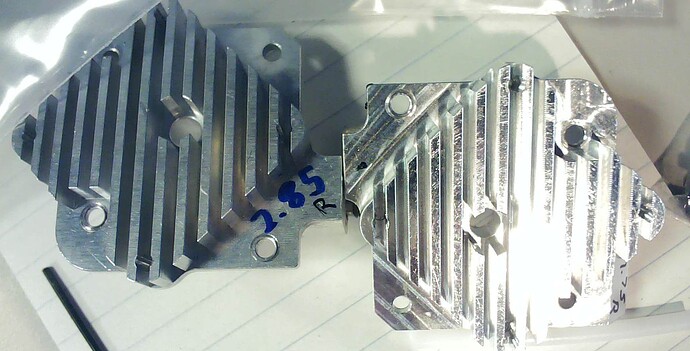

To do it (close to) properly, you need 1.75mm feed tubes (normal and mirrored) ($5), two 1.75mm V6 heat breaks ($26), 1.75mm nozzles ($cheap to expen$ive depending on your taste… I’d go with hardened steel CHT clones) and Titan Aero 1.75mm heatsinks (normal and mirrored) ($30). But… the standard titan aero heatsink is 3mm shorter than the Lulzbot version:

So if you only swap these things, the part cooling shroud is now going to crash into things.

So do all of the above, then make a custom part cooling shroud that is at least 3mm thinner than the boxy stock version. This is the last version I was using.

Circleshroud dual v1.5.stl (4.0 MB)

After all this, it still wasn’t great at PLA, but did work. The end cost for all the parts was under $100 with everything shipped.

I’m working on doing a major upgrade by converting my personal Pro DE to a dual orbiter w/CHC (or maybe Revo) hot ends, but that’s probably a few months away, and I haven’t designed the part cooling yet.

I swapped out the Aeros for Hemeras on my work’s Pro DE, and they’re amazing… but too expensive for my personal machine.

Wow! This more than thoroughly answered my question, and in great detail. Thank you so much for this. Obviously it doesn’t sound like its worth all the trouble. I was just hoping I would only need to modify one or two things, haha. Not a big deal. Thank you again!