Recently I have been chasing some issues with my Lulzbot Mini 2 with ringing on prints and uneven first layers depending on where I print on the bed.

First off, all of my prints have been in PLA, either eSun or Polymaker 2.85.

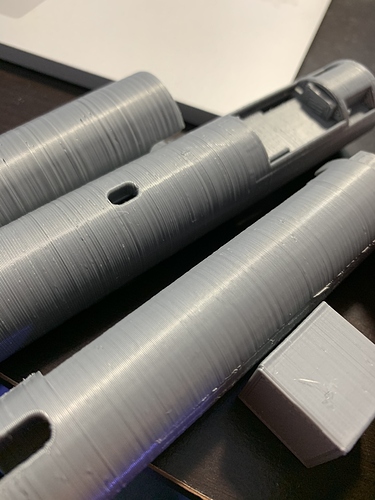

When I am able to print a good first layer and complete a print, I was getting terrible periodic ringing up the. It did slightly improve with calibration of XYZ steps using 20mm cubes. But it still leaves ringing all the way up.

The far left cylindrical piece was the initial results and it progresses right as I made adjustments. The cube is the best piece I’ve gotten to print but it still has what I consider to be pretty bad ringing.

I have calibrated esteps several times, checked the print bed with a straight edge for divots and high spots, and checked all hardware for tightness along with the belt tension of all axes.

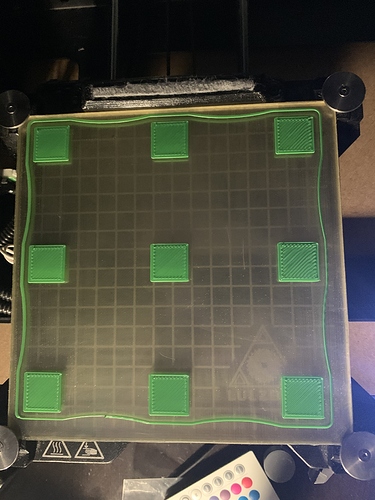

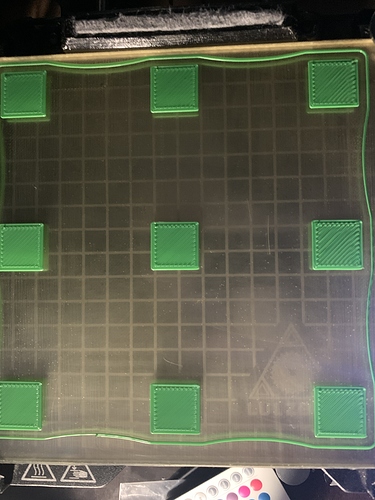

When printing an array of 20x20mm first layers I noticed that the nozzle is much tighter to the bed on the left side than on the right. The center gets very nice first layers, the left look good but a little tight on the z-offset, but the right side of the bed is horrible.

This is most prominent in the skirt, with the left side very thin and pressed to the bed, and the right is barely pressed to the bed. When printing the second skirt line, the right side of the skirt almost always looks as if it is on top of the first line. This goes away with higher z-offset but at that point there is little to no bed adhesion.

Has anyone ran into any of these issues or have any suggestions? I have calibrated everything I can think of, tried different printing temperatures, speeds, first layer heights, jerk, acceleration, etc

The specs for the best print I was able to get were:

Initial layer height: 0.4mm

Layer height: 0.25 mm

Line thickness: 0.5mm

Initial line thickness: 125%

Temp: 190C (195 initial)

Bed: 60C (65 initial)

Print speed: 40 mm/s

Lowered all acceleration and jerk by about 25-50%

I can copy and paste more if needed but I am currently on my phone.

Layer heights were unchanged throughout, other than minor changes to the initial layer, as I do not want to sacrifice the 0.25 mm layer height.

Finally, is it normal for the clunking to be so loud when printing lines for the floor/roof of prints? That combined with a sort of “helicopter” sort of “dudududu” noise, but only when printing the lines. I have a video I will post but it is not letting me right now. It’s hard to hear in the video but try to listen past just the back and forth of the bed/print head. I must admit my phone’s camera makes it sound much more violent than it truly is.

All belt tensions seem okay, all hardware is tight, none of the rods are dirty or appear bent, and everything moves freely as far as I can tell.

I am just really disappointed at how this printer is performing as we have the same model in the lab I work in and I have been able to get nice prints with the same sort of parts on that machine.