I recently picked up a couple rolls as I have some prototypes that needed more stiffness than PET, and more slickness than ABS. This material really prints sweet. Extreme overhang printability, super solid and rigid prototypes. Works great for gears. I’ll post up a print later on something that isn’t under NDA.

What settings are you using for nGen? My results are not as good. Oozing and stringy.

And I tried to print with nGen and dissolvable PVA. Seems like the nGen doesn’t adhere to the PVA, so the interface is as bad as if I just broke support away.

I’m using simplify 3d. 225C hot end, 80C bed temp, 100% flow rate, 1.7mm retraction 50mm/sec print speed. The only thing I changed from the ABS profile was the temps and flow rate as I’ve had to run abs at 90% to not get overextrusion after calibrating the extrude. I’m using the older taz5 with the .35mm nozzle

nGen is pretty much my “go to” filament too. I’m anxious to see what ColorFabb’s new HT filament is all about when it comes out.

Lowered temp to 225, then a bit more to 222. Increased retraction to 1.7, then a bit more to 2. Still have oozing. Prints are stringy and fuzzy. I wonder if your smaller 0.35 tip helps with the ooze. I have 0.5.

I’m using a Mini so it’s a 0.5 mm tip. I think it might be your flow. I’m running 225° nozzle & 1.7 retraction, but my flow is at 90%. No oozing, and some, but minimal strings.

I will say that my bowden equipped Makeit pro has a little stringyness, but I’ve found that for a few different filaments on that printer. The Taz has a few hairs more than strings, but generally nothing that can’t be just wiped off with a finger. The .35 tip may be the difference, not sure.

How does Ngen compare to Nvent?

nGen is an Eastman Amphora 3300 co-polymer and N-Vent is an Eastman 1800 co-polymer. N-Vent is closer in similarity to ColorFabb XT and Inova 1800. Those print at a little higher heat and are a little stronger than nGen. They all have a similar sheen when printed. They all sort of fall in between ABS and PLA with less warping than ABS and better strength and heat resistance than PLA. nGen is a little closer to PLA in look and performance but easier to print, stronger, and better heat resistance, and N-Vent, XT, and Inova 1800 are closer to ABS but easier to print with better layer adhesion and stronger. Actually I’d say N-Vent, XT, and Inova 1800 are probably closer to a PET or PETG.

Thanks! Why do you prefer nGen over N-Vent/Inova 1800? I am looking for what prints easier and stronger. Sounds like you think they both print easier and nGen has better performance?

For my purposes, nGen prints the easiest of all except for possibly HIPS and PETG (that’s just from my experience). However, Inova, N-Vent, and XT are actually stronger than nGen, but have lower heat resistance. My prints are exposed to heat quit a bit and so far nGen holds up well. I do also use XT, Inova, and N-Vent when my parts need a little more strength or dimensional accuracy, but nGen is just an easy and reliable filament for me.

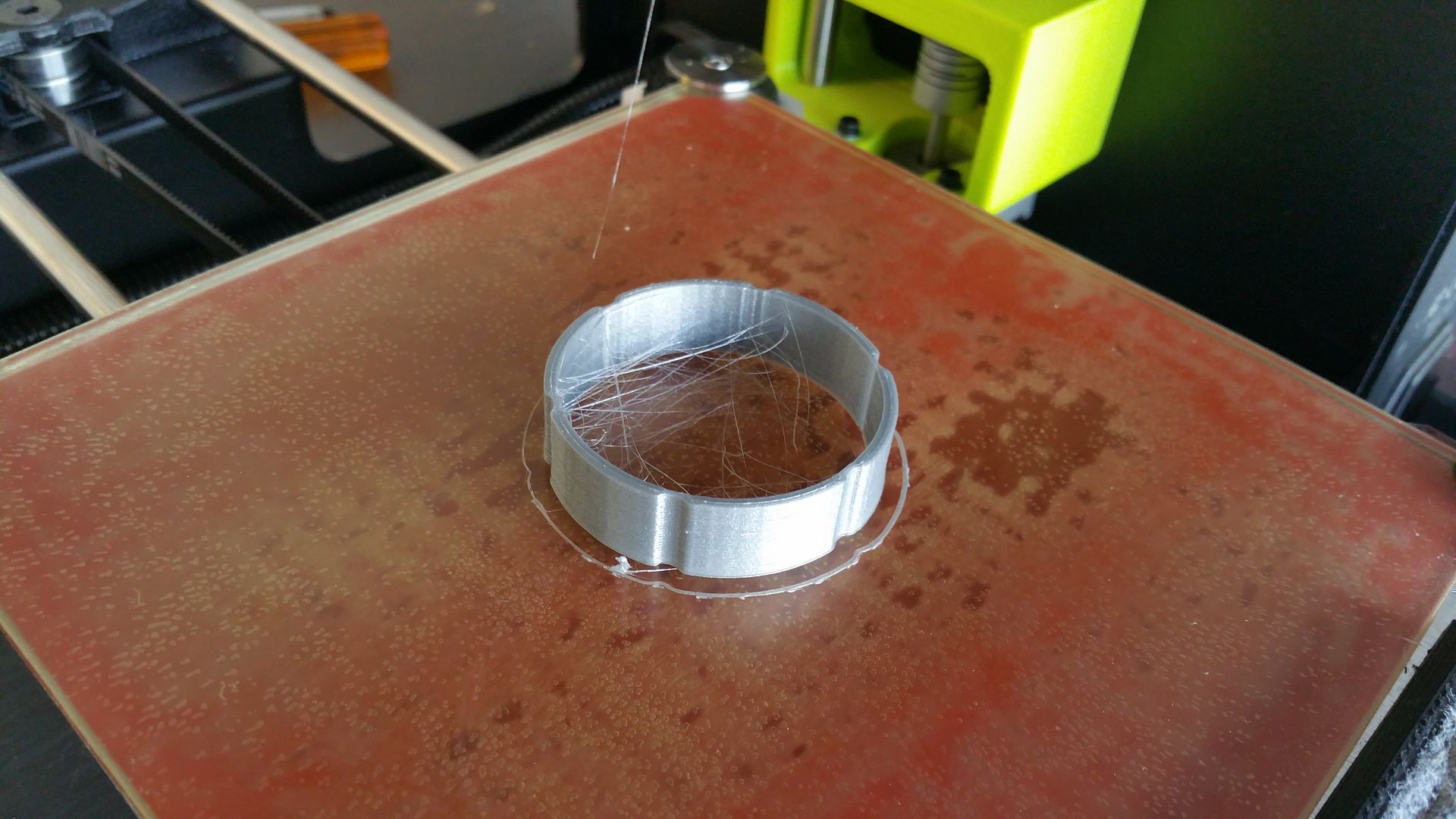

I have been using Ngen from the start but of recently I have been getting a lot of strings. I tried the suggestions that have been posted in this thread but it has not changed. I have a Lulzbot Mini. I ran over a dozen of the parts of the picture I have attached before it started to get stringy.

Would speed change this?

I have also noticed that my perimeter around the print isn’t a full line width but that may not be a filament issue.

You might try reducing the nozzle temp a few degrees, but if it printed dozen parts fine and then started getting stringy and having reduced flow, then you may have a partial clog.

So how would you go about clearing a clog?

Stringiness is a sign of printing too hot and not enough retraction. Could also be a dirty nozzle.

Lower the extrusion temps as suggested above… a few degrees, I’d slowly lower 2-5C. You can change the temp on the fly, but give it time to stabilize before lowering again.

Next, try increasing the retraction by increments of .1. This more retraction will create more suction in nozzle to keep “suck” up the filament, and until the nozzle move is complete.

Its going to be a combination of those two parameters. The key may be upper layer separation. For tall prints you want good layer adhesion, otherwise it may split… this may not be the case for Ngen, but definitely the case for ABS. Obviously if you lower the temp too much to rid the stringiness, it may not print tall objects very well. Increase the temp, then work on the retraction… etc.

If your slicer has a “Coast” setting, set it to .2-.3.