I have a stock bed on my Taz 6 and would like to switch it to a straight glass bed. Can anyone explain what I would need to change other than the surface itself? (bed leveler corners, heat plate, etc.)

Stock bed on the Taz6 is (borosilicate) glass with a PEI sheet. You can remove the PEI from it if it’s damaged and replace it, but there’s almost zero materials that print better on bare glass vs PEI.

To remove the PEI sheet, just remove the entire bed, put it in the freezer for an hour or two (the adhesive loses strength when cold), and peel it off. Adhesive residue will take a fair amount of scraping and isopropyl alcohol to remove, but is more tedious than difficult.

Thanks for the info. We have a taz 5 at work with a glass bed and it gets a glassy finish on the side that prints to the bed. Haven’t had a ton of trouble with it sticking using purple glue stick but also don’t use it but once or twice a year.

Goo Gone will take off the adhesive off really easily, but avoid getting on the adhesive for the heating pad. I used to use it all the time to clean off the adhesives on used glass plates. The adhesive will pretty much just rub/scrape off after some time just soaking with the Goo Gone! Then just wipe with Isopropyl to get the Orange oil(aka - Goo Gone) off the glass.

I used a razor blade scraper before using anything else.

Oh, and another tip for those doing this - do it outdoors or a very well ventilated area. That 3M adhesive has a very strong odor, and probably full of bad VOCs.

Follow up question. Is there a way to change the Taz 6 bed so it has some adjustment capability for leveling? If I level my Y axis rods to the bed the Z threads squeal when going up and down which makes me think they are not at 90° to one another. So then the bed would need to be leveled some.

Could be the entire frame is out of square from not being on a level surface.

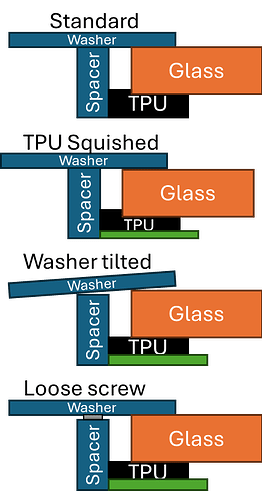

You can do a little bit of adjusting by shimming under the bed, but the way the washers are designed, the bed rests on the TPU pads, then the washers are tensioned down upon the spacers, which squishes the bed into the TPU. Adding shims will either be small enough that the TPU just absorbs the height increase, resulting in no change in height, or may be big enough that the washer no longer sits flat on the glass, or if you leave the screw loose (not recommended) you can get the washer flat, leading to a physical change at the expense of losing tension over time.

To do actual physical height change, you need a shim that goes under the TPU and the spacer. I had one that I used for a little while, but just ended up going with BLTouch.

Thanks for the info. I have a bltouch on it which tests before each print but I was still experiencing some issues with the first layer not printing uniform. You may not remember but you and Zenotek helped me get it set up a year or 2 ago.

Ideally, I would like to swap the bed out for something that is adjustable, like the taz 5 has but I haven’t been able to find anything online where someone has done this. The PEI surface definitely needs replacing as it is starting to bubble up in certain areas, hence the initial question of switching to glass. I understand this is an older printer so most people have moved on from attempting to modify it, but it has been reliable and seems to be built like a beast.

So if you’re running BLTouch now, you don’t need to worry about the washer calibration. You can loosen the washers, slip a shim between the TPU and glass. Since looseness of the washers won’t affect the Z offset between corners, you only need to check that the screws aren’t getting too loose occasionally. It’s what I did to level out my bed after moving to BLTouch.

Thanks again. I will give that a try.