New project! This time I want to see if I can’t eliminate the X axis deflection from the unsupported rails of the TAZ. The project should be 100% bolt on, no firmware upgrades required, using existing hardware as much as possible. You will need some heat set inserts and some bolts, along with the following Openbuilds Openrail components:

1 60mm x 20mm Openbuilds linear extrusion, final length to be determined. http://openbuildspartstore.com/black-v-slot-linear-rail/

4 sets of bearing wheels (http://openbuildspartstore.com/xtreme-solid-v-wheel-kit/ or other sets) ,

2 spacers (6mm probably) http://openbuildspartstore.com/aluminum-spacers/

2 eccentric spacers http://openbuildspartstore.com/eccentric-spacer/

one of their Gantry mounting plates. http://openbuildspartstore.com/v-slot-gantry-plates/

Bolts and nuts (M5, Lengths to be determined.)

I’ll get more specific on that when i get closer to having this operational, but I am still tuning some of this so part list may change

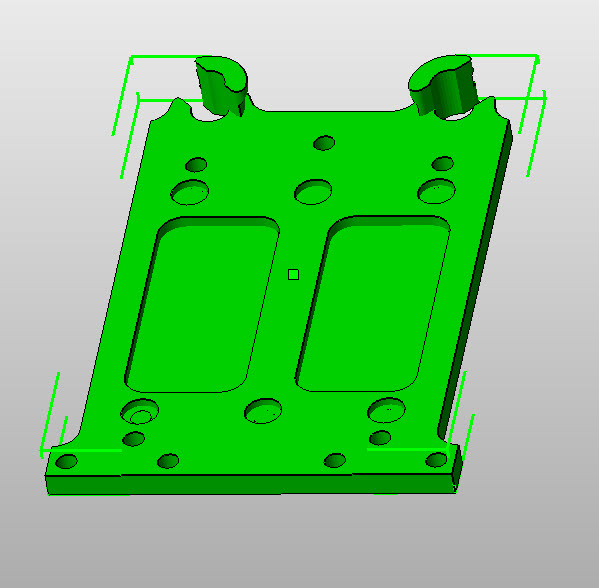

This bolts in place of the existing X axis printed pieces. I wanted to include a Y belt tensioner, so the idler pully can be adjusted inwards. I’m not 100% happy with what I came up with for the motor mount, but its about the only way it fits in there without drilling holes in the openrail so you can screw the motor in place or offsetting the mounting points a rediculous amount. There will be a Taz style plate overlay for the gantry plate for now, I may work up something different further into this one. Right now the X carriage will have about twice the mass of the stock TAZ one, but there will be zero bearing deflection. For me that trade off is worth it, but I intend to try and shed as much weight from the carriage parts as I can where it is safe to do so.

Design files. These are Open source, Attribution under the GNU/GPL V3 open source license. As always, other formats are available upon request.

Taz_OpenRail_Xmotor_Mount_lid_1_0_a.stl (163 KB)

Taz_OpenRail_XMotor_Endcap_8_4_b.stl (239 KB)

Taz_Openrail_X_belt_bracket_1_0_a.stl (131 KB)

Taz_OpenRail_Idler_Tensioner_1_0_a.stl (211 KB)

Taz_OpenRail_Idler_Endcap_1_0_a.stl (298 KB)

Another file

Edit: I’ll post some better assembly pictures once I get a bit more things tuned. I need some longer bolts for the X carriage or a redesign of the back bracket (metal plate is a possibility) and I need to get all the actoual mounting hardware on them. The belt tensioner works by tightening the two screws that protrude outside the endcap. once the belt is tightened, two M5 bolts are bolted to the openrail itself, locking the idler in place.

The X motor mount seems to be pretty solid. I am worried that it will work loose over time, and there just isn’t really room to use the larger M5 heat set inserts there. I can’t bolt it from the other side because then you can’t attach the assembly to the rail. If anyone has a better idea for mounting that in the space available, with the understanding that it has to be all the way over at the edge to not lose X travel, please let me know.

Taz_Openrail_xmotor_Mount_mainblock_1_0_a.stl (318 KB)

This will also fit my AO-10x ballscrew modification by the way.

I’ve decided the back bracket is going to have to be a plate. Anything I can print strong enough is going to be too heavy.

I actually have a half drawn y axis modification along those lines. It probably is going to require a y bed plate modification as well so that isn’t ready to go yet. The open rail x mod is about the same volume level near as I can tell. It might be a little quieter from some angles due to the mass between the motor.

This is fantastic!

Would you be willing to share the parts in a parametric format like .ipt?

The forum apperently isn’t going to let me attach an ipt file here, or at 15mb it’s too big. I have no problem at all sending you the file though if you want to PM me a location i can post it to, or an e-mail I can send it to that will accept a larger file.

Definitly no problem sharing this or any of my other open source projects in whatever format I can output to that will help.

Thank you for that. Here is the link to the IPT file there for anyone who wants it. There will be several more parts and changes in the next few days. http://cloud.itsolutionnc.com/public.php?service=files&t=25936c5212741fb9e00365c66248a7f8

I’ll also be upluading the DXF file for the metal backplate sometime later today.

Parts that are still pending design:

- The X carriage lower mount adaptor

- The X carriage upper mount adaptor

- backplate

- Optional X axis cable chain adaptor

- Optional Z axis cable chain adaptor

Here are the files for the metal backplate attempt. Same file, different formats.

Taz_Openbuild_X.dxf (224 KB)

Taz_Openbuild_X.dwg (48.5 KB)

X Carriage adaptor plate. This will allow you to mount existing Lulzbot Taz style toolheads to the Openbuilds X carriage plate. It requires 3mm heat set inserts. You will also need to reuse or print the X carriage guide plate (http://download.lulzbot.com/TAZ/5.0_0.5noz/production_parts/printed_parts/x_carriage_guide/)

Taz_Openbuild_X_Carriage_1_0_a.stl (274 KB)

Thank you piercet… looks good!

Here is the printed version of the tool head mount. I am probably going to move the mounting bolt location slightly inboard to allow for easier assembly, so I’ll post that STL once it’s done, but here is the general idea. This uses the stock Lulzbot toolhead mount retainer thingy.

Also, truly awesome forumite cnr0616 (Aka Craig) has access to a laser cutter and was able to cut the backplate piece out of Aluminum plate for me. I You can see the belt mount nubs, those will probably get thinner aluminum pipe covers and smaller washers, but they are plenty solid as is. Both ends of the belt anchor there, then the belt adjuster is on the Idler pulley side. The whole assembly is absolutely rock solid, no play or wobble at all, smooth as butter, and shiny to boot!

I can’t say enough good things about cnr0616 though, Thank you again!

I’ll probably get the actual rail mounted sometime this weekend and start trying it out. There will also be an auto leveling mount for this as well still to come.

New parts today. I’m getting ready to actually bolt the assembly onto the machine, and I decided I wanted to try to reinforce the motor mount a bit more by adding M5 heat set inserts in place of the M3 inserts. I think that will be much more survivable long term. I also redid the mount platform to move the screw holes over slightly to make mounting easier.

Taz_Openbuild_X_Carriage_1_2_a.stl (242 KB)

Taz_Openrail_xmotor_Mount_mainblock_2_0_a1.stl (385 KB)

Taz_OpenRail_Xmotor_Mount_lid_2_0_a.stl (189 KB)

Alright, back from my weeklong training class, finally got this bolted on. Here’s a quick video of it in action. More pictures, assembly instructions etc. to come.

http://youtu.be/IsBAXx0Zjm0