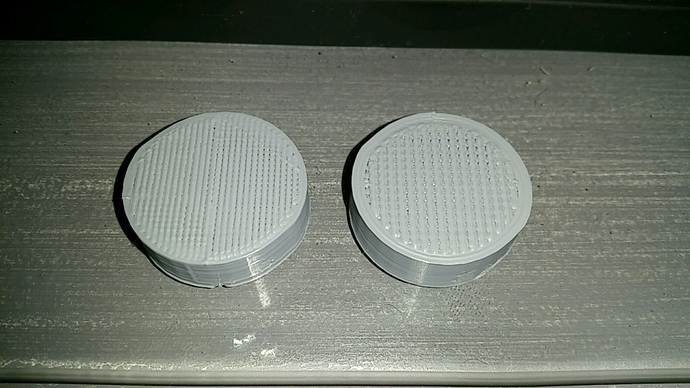

All of my prints have extremely rough top and bottom infill layers. It looks like the printer is skipping every other line and covering the same lines twice with filament. I’ve tried switching slicers from Cura to Slic3r, yet the problem persists. I’ve also tried changing the flow rate, yet the problem persists. I’ve tried changing the top/bottom layer fill pattern in Slic3r, and that helps a little bit but it’s still protruding very far out of the top of the print. I haven’t found another user with this problem anywhere online. I’m not sure if this is an issue with the machine itself or with the software. This is a brand new printer. Everything else about it seems to be absolutely perfect. Any ideas?

Is this pla or abs? Do you have a higher resolution picture of the issue?

This is PLA. Here’s another picture of the issue. The piece on the left was sliced with Cura, and the piece on the right was sliced with Slic3r. I find it interesting that the layers are significantly different.

You may need more cooling fan there. But the root problem is either you have zero solid top layers set, or you have something very odd in your profile. I would consider downloading a fresh starter profile and starting over if the solid top layer increase doesn’t do the trick.

Resetting the profile didn’t change anything. But I did notice that the y-axis belt was really loose. I tightened it and… it’s still happening.

Hmm, the default Lulzbot issued profiles downloadable from download.lulzbot.com should be fine. Is there any chance you have it set to a 0.35mm nozzle and you actually have a 0.5mm nozzle fitted? The minis all shipped with a 0.5mm by default. The final layer spacing looks like what you get if you have a smaller nozzle than the printer is expecting, but the rest of the print looks decent, which generally wouldn’t be the case in that scenario. Can you post the stl file here? maybe there is something odd going on with that top layer. It’s definitly looking like it’s just printing 60% or so infil up to the top, then just stopping. Usually it would do 2 or 3 solid layers noticibly different in pattern and tecture at the very top.

That’s not infill. That’s the screen door effect.

Either:

- Measure your filament diameter and put the correct diameter into the profile. If you’ve done that then:

\ - Increase your flow (%) by 1-2% and print again. See if it gets better. Keep upping by 1% until the holes close up. Don’t go too far because it can cause other issues. You want to be able to see each printed line pass, but lines next to each other should be touching.

That should get you running. Ideally what you need to do is calibrate your extruder eventually. How to do that can be found here:

https://ohai.lulzbot.com/project/fine-tune-mini-extruder/calibration/

Jim

Before I try recalibrating the nozzle, though, I wonder if THIS might have anything to do with the issue:

And before you ask, no, it isn’t actually touching or covering up the end of the nozzle. This just showed up today.

Leaky heat break. Time to call Lulzbot for a warranty return ASAP.