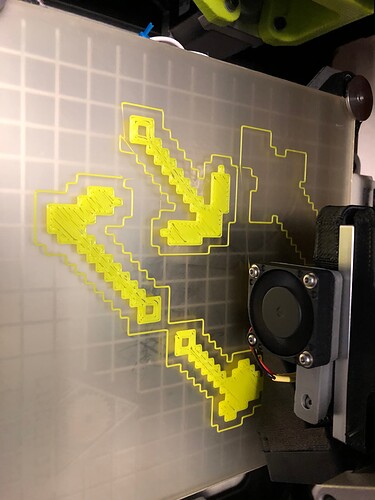

Hi, I have a Lulzbot Mini 1 that having trouble with the first layer or so. As you can see from the photo there are gaps. After the first layer or two there aren’t really issues with the prints I am doing but some prints are really effected by these gaps in the initial layers. Do you have any idea what is causing this? Thanks!

First thing to check is your Z-offset. Next thing I’d check is the E-steps calibration. Does it do this with different filaments (i.e. a different color of the same filament)? What tool head are you using? Make sure the hobbed bolt is clean. What have you changed recently (i.e. since the last time you had successful prints)?

Thank you for your reply. I can definitely look into my Z-offset and E-steps calibration. I assume I can find information about doing that on the forum or a Google search.

I have tried all different colors/filaments so I don’t think I don’t think the filament is the problem.

I am using the original factory toolhead with a 0.5 nozzle and the filament size is all the same for the most part (2.85-3.00).

I will clean out the hobbed bolt and see if that makes a difference.

I changed out the bed (the glass and the heating element). The previous factory bed’s glass got cracked so I changed to a new glass with the standard PEI surface. The heating element is different. I switched to LulzBot Mini Etched Modular Print Bed Heater. I also added an additional fan to the toolhead to prevent heat creep. Additionally, I needed to replace to Y Axis Idler Mount because it was cracked.

You can search this forum (or others) for the E-steps calibration procedure.

Since you changed the bed, I’d put my money on needing a Z-offset adjustment.

Since Z-height calibration is based off the corner washers thickness the new bed has nothing to do with it. The possible thickness difference between each washer can have some effect though, so try to put them back in the same location. When I use to refurbished printers I found different thickness washers some times.

I’m sorry @kmanley57 but you are completely wrong. The difference between the plane established by the four corner washers and the plane that represents the actual bed surface is very much what the Z-offset is used for.

To quote from https://ohai.lulzbot.com/project/TAZ-OctoGrab/accessories/:

The LulzBot Magnetic Build Plate System will require your z-offset to be adjusted positively to account for the added thickness of the spring steel plate.

Use the graphical LCD on your printer or Cura’s printer console to adjust your z-offset positively by 1.50mm prior to printing to avoid damaging your build surface.

For example, if your z-offset is currently set to -1.20, change it to 0.30mm. (-1.20+1.50=0.30mm)

Adjust your offset down as necessary to lower your nozzle closer to your build surface.

A guide for adjusting your z-offset can be found linked below.

UH! That is the Taz one not the Mini that he did. Pretty much the same but wrong printer link.

The link was “wrong” but you missed the point of my post, Changing the bed can change the Z-offset.

From https://ohai.lulzbot.com/project/Mini-OctoGrab/accessories/:

The LulzBot Magnetic Build Plate System will require your z-offset to be adjusted positively to account for the added thickness of the spring steel plate.

Use the graphical LCD on your printer or Cura’s printer console to adjust your z-offset positively by 1.50mm prior to printing to avoid damaging your build surface.

For example, if your z-offset is currently set to -1.20, change it to 0.30mm. (-1.20+1.50=0.30mm)

Adjust your offset down as necessary to lower your nozzle closer to your build surface.

A guide for adjusting your z-offset can be found linked below.

From the pictures, it looks fairly uniformly wrong, so it’s probably a z offset issue, but a few things to check, since you had the bed off and may have bumped things:

First, wipe down the new bed and make sure it’s clean!

Check that the screws at the corners are all tightened down as well. If one is loose, the Z offset will be wrong as that side will have more potential space between the washer height and the bed.

Second, try and slip a piece of paper between the washer and the bed at all four corners. If anything can make it into that gap, the screw is not fully tightened down, or the flexible pad under the bed has been deformed and needs to be replaced.

Third, verify that the gantry is parallel to the bed. If you manually lower the gantry to about 40-50mm above the bed, you can slide an object under on one side of the gantry, lowering it until it just barely fits in the gap, then moving the object to the other side of the bed to see if it barely fits on that side too. If it’s off by more than a few tenths of a millimeter, disable the steppers in the motion menu, and alternate rotating the threaded rods at each end until the object is equally close to the gantry and both sides.

Probably right on z being off. Was the new PEI plate abraded with ScotchBrite or similar? Might slower speed or slight temperature bump help?