Lately, my prints have been coming out extremely stringy and hairy. They would only print halfway, and when I try to get the mess off the build plate, it won’t come off. Before this, it was not printing at all. only half of the outer ring it makes was printing. I have tried multiple filaments; none work. Some prints, it prints part of it ok, and the rest is just a stringy mess. Does anyone know how I can fix this?

Nozzle is too close to the bed.

If you haven’t been doing any adjustments to the Z offset, it’s almost certainly because your nozzle is not actually clean. It’s imperative that the nozzle be spotless for the bed leveling to work right. If there is any visible movement of the bed when the nozzle touches a corner, the print will end up like this one.

The nozzle wipe before a print should be only considered a dust removal. It’s not very good at removing plastic, especially PLA.

Additionally, the bed should be very clean, with maybe a bit of PVA gluestick on it.

The Z offset should be around -1.25 to -1.32 for the PEI coated bed.

It’s still mashed into the bed, raise the Z offset by about .05mm - 0.1mm

Clean the hell out of the nozzle too. The factory nozzles are not soft brass, so you can really clean them before the probing. If there’s any plastic visible in your scrub pad, (especially PLA) it can re-deposit on the nozzle during the wipe, so ensure that’s not a source of contamination.

The skirt looks almost ok, because there’s room on two lines for filament to push outward, but once you get to the lines that are three or more thick, it can only go up, where it catches the nozzle on subsequent passes, or sticks to the nozzle.

Sorry for the late response But I have been trying lots of things to fix my problem (Nothing worked) But now I have a new problem. When I try to move the Z axis it just wont move. It will just make a buzzing noise. Do you know how I can fix this?

Buzzing isn’t good.

Could be jammed due to gunked up rods, out-of-square frame, bad stepper motor(s) or bad stepper driver.

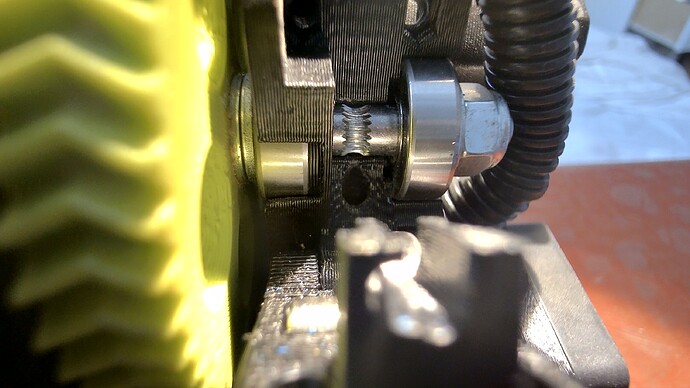

Loosen the grub screws that connect the Z motors to the dampers on both sides (2 per Z motor), and see if the motors turn smoothly. If they continue to vibrate in unison = I’d say bad stepper driver. If one vibrates, bad stepper. If they turn just fine, could still be bad driver, but a misaligned or jammed gantry would be my guess.

Hi what I see is that sometimes when I leave it alone for several days it will start working again but if I during the print I abort the print it will buzz and then again the buzzing of when I try to move it in the z axis starts again. Also I wanted to ask how do I loosen the grub screws?

2mm Hex - as seen here:

Good call. I was printing several prints perfect all weekend long then suddenly things wouldn’t stay down. I wondered about the Z screws wandering around, since I’ve discovered many loose screws throughout.

I’ll check that!

Also forgot to mention. This started happening after I flashed new firmware. I have tried slowing down the build speed it didn’t work.

What toolhead do you have? If you flashed the firmware, it would have reset to a default toolhead, which might not match what you have.

I’m not sure what my toolhead is because the printer was given to me but I think its probably the standard one I don’t think they made many changes to the printer.

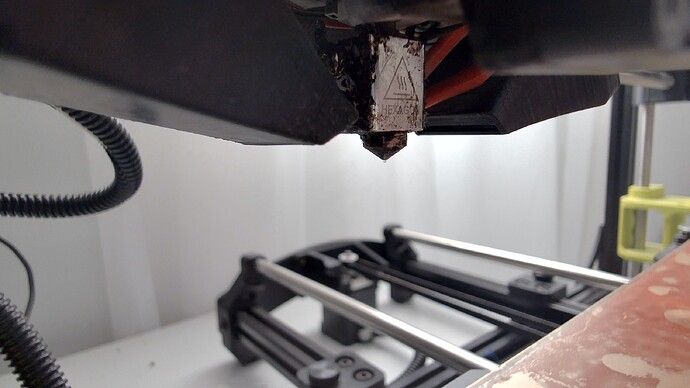

Please attach a picture of your toolhead so we can help you identify which one you have.

That’s the Taz6 Standard Extruder (not to be confused with the SE).

They use a hobbed bolt to drive the filament, so the extruder steps is a little different for each one. It should be on a sticker on the back plate of the extruder, or you can measure it yourself. It should be what is loaded as the default toolhead with new firmware. The default steps/mm should be close enough to get a print better than what you have there.

But the toolhead is not great at pushing PLA, it has a tendency to strip (grind) PLA. Open the idler arm and send a picture of your hobbed bolt’s teeth. Any stripping clogs them, leading to more stripping… leading to more clogs and underextrusion.

Not enough pixels to really tell condition of the teeth in there, but based on the condition of the guide, you’ve got some serious wear going on.

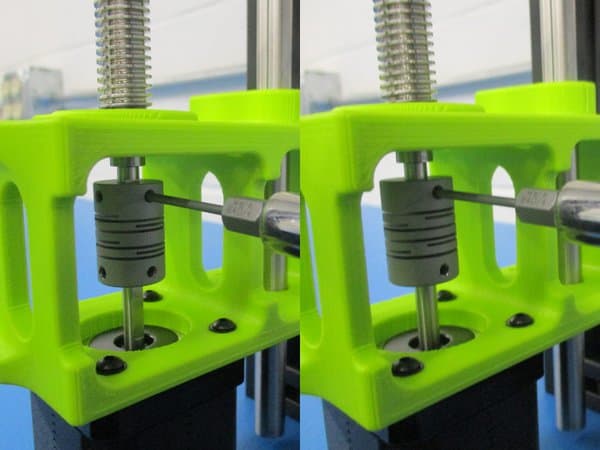

New:

There may be other wear in the filament guide that’s making it easier for the filament to avoid the gears as well. Check this area:

I’ve seen it worn enough that there was a groove in the side of the top of the heatsink before, so check the entire filament path.

I found the problem when I installed cura on my new computer the bed was set smaller than what I actually had on my computer. Thanks for all the help!