I was really lucky to buy a Mini from another member here who had it for parts. I already had a Mini 1.04 and it’s been a great solid printer. I print for fun, but also print some parts that are used in production. With a tight budget I started looking for another printer to fill the production need. The Lulzbot printers were way out of range at the moment, so I was looking for “cheap” printers before this opportunity came up. Now I can run the same gcode on both!

The background on the printer was it was not working, there were issues with the extrusion and the previous owner had purchased a new Z axis and Extruder harness from Lulzbot. There were are a few parts and bolt missing, nothing that couldn’t be replaced. I also knew the Mini was in the 1.03 range of printers so I also wanted to get it up to the 1.04 to match my current printer. I made an assumption that the rambo board needed to get upgraded becuase the 1.04 uses a different board and it may be why the extruder wasn’t working since the harness is new. So I ordered a Rambo Mini as well before the printer had arrived. To my surprise, they both arrived on the same day. I also wasn’t worried about the printer not having an extruder since I had a second one.

Now I got excited and started working on it right away so I am missing some pics, but I’m not done so I’ll try to be better at that.

The front idler was broken so I replaced that with a 1.04 idler in Chroma Strands Lulzbot green. This was also so I could visually tell the two printers apart. I also added a stepper damper to the rear motor

Next step was to install the new board, I’m missing a few a pics here. I unplugged everything, replaced it and went to work. I followed the z and extruder harness and decided to take it all apart to tie down the harness like in the production notes. On thing I noticed the ferrites were different on this printer than my 1.04. On the 4 the ferrite it integrated into the harness. Seeing that the new harness had one I tore out the individual old ones and added one from the parts jar to the lowers. Here’s what I ended up with.

I added the extruder, I had also printed a new top wire cover and fan duct in green so I can tell it apart. This head will eventually have a .8 nozzle. I’ll have black for .5 and grey for .25. I also made a modified spool arm for 5lb spools. It uses some 2020 for the body so that the height can be adjusted. Finally the printer was ready to test and see how it works.

I got positioned the printer in it’s new home and loaded up a reel of IC3D Grey ABS. I like printing with ABS because I’ve never had good success with PLA. I know it’s said that ABS is hard to print, but for me it’s been less finicky than PLA as long as the first layer is good. I’m having better luck though after switching to Titan Aero heads instead of the 1.04 hexagon head.

Anyway, the extruded warms up just fine. I load filament and extrude a few MM to get it going. Then load up a rocktopus and begin to print. Almost right away I get a thermal run away error. I reset and try again. Same thing, so I figured it was the bed this time since the extruded worked great, and everything else moves and homes correctly. Time to take it apart again.

This time I decided to rip out the entire bed heater harness and started doing continuity tests. There it was, one of the bed heating wires was bad and the bed was not heating. At this point I noticed the harness was different than the 4 as well. The cable drag chain was wider than the 3 and the wires were pretty bunched up which was part of the reason for the wire failing. It was also 14ga and very stiff wire. After looking over the wire harness documentation and BOM of the 4 I saw they switched from 14ga to 16ga wire. I got the wider cable drag chain from McMaster and some super flexible silicone wire from Amazon.

While I’m waiting for parts I notice the bed that came with it needed a new PEI sheet. Since I had upgraded to the modular bed on my 4 I pulled the original bed out and installed that. One of the things I do not like about the 3 is the bed mounting plate compared to the 4. The bed corners make it more difficult to center the bed and the spacers for the leveling disks are dinky in comparison. I’m working on sourcing an updated bed from Lulzbot if possible. In the mean time I printed some new bed corners with Cheetah TPU in hopes it will help centering.

Time for surgery. It was pretty straight forward, I transferred everything over to the new drag chain and made sure everything worked. So now it was time to try to the roctopus again.

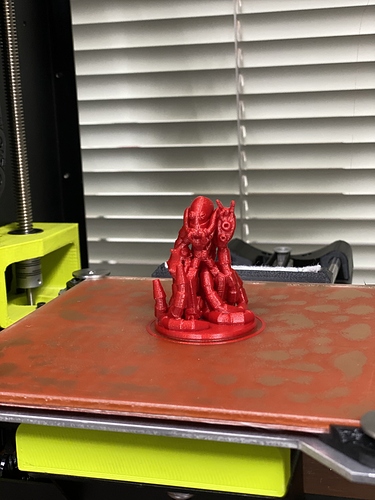

Before the roctopus, I found the burn in gcode and ran that just to see if everything was working correctly. Fun fact, that gcode doesn’t warm up the bed, so I still didn’t know if it fixed the problem. I did notice that the 3 is a lot louder than the 4. I think it’s mostly because of the Z axis motors not being Moons and lacking a dampener. I think that’s next. So now I loaded the code for the roctopus and and it went off without a hitch. I printed for speed and not detail because I just wanted to make sure it all worked. Success!