I received my new Mini 2 about a week ago. Out of the box the rocktopus printed perfectly. Using the same green filament, I then printed two small parts (the lid for a Raspberry Pi case, so about 4" x 2", and the faceplate for a Raspberry Pi camera, maybe 1" x 1"). These also came out perfectly, and that mostly used up the green filament.

Before I go on, I’ll explain that experience-wise, many years ago (10? more?) I had a little Cube3D but got tired of the vendor-lock-in filament. We upgraded to a factory-built printrBot that never really worked right so I sold it – probably 5 years ago. But I’m reasonably familiar with casual-hobbyist basics, although it has been awhile.

I switched to the included white sample filament, same make (Polymaker Polylite PLA). I extruded until it ran white and extrusion looked smooth so I tried to print. So far I haven’t had a single successful print. The first three tries, it didn’t stick to the bed at all and just made a tangled mess on the hot end. It wouldn’t even complete part of that outline it starts with (which I assume primes the extruder).

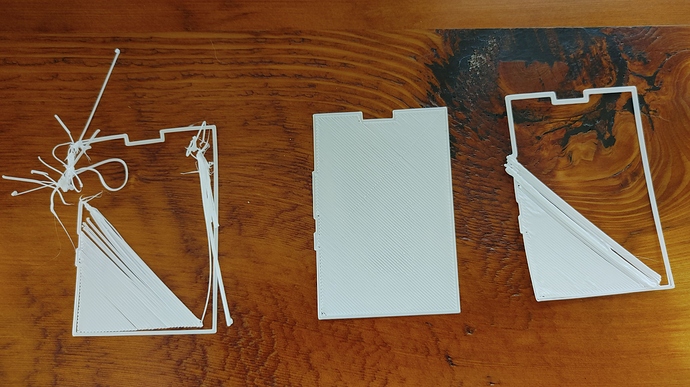

I cleaned up the bed really well (just a damp cloth, had no alcohol on hand at the time) and it seemed to work. I was trying to print the bottom part of that Raspberry Pi case, so most of the print was another flat 4" x 2" rectangle with some walls at the end. It laid out the perimeter ok and started the infill, and about a quarter of the way through it started pulling up the infill and was soon dragging the whole mess around the bed again.

More cleanup, and this time I used the glue stick. I know it isn’t supposed to be needed with PLA but I had no other ideas. The next try seemed to be going well. I got two completely filled layers down. I still have that piece, for just two layers it looks pretty good. But the third layer didn’t stick at all and soon I had another mess dragging around.

Cleanup again, this time with water for the glue, then alcohol pads. No glue this time. It laid down the perimeter fine, but the infill was looking sort of blobby and lumpy. About a third of the way through the first infill layer, the infilled corner started curling upwards, and the extruded plastic started partially tearing previous passes away, so I aborted it. Here are pictures of all three that made it to various stages.

Since it’s new, Support suggested I check belt tension, screws, etc. so I’ll be fiddling with that this afternoon. Also some settings changes they offered because the wipe process isn’t aligned correctly with the pad.

For the adhesion problems they suggested I adjust my z offset down a little bit. I’m not sure what constitutes “a little bit” and I’d like some advice on that. I still need to dig around in Cura and figure out exactly how to do that, too.

Initially they suggested maybe I needed to bump the heat up, although I didn’t get answers to a follow-up question for clarification. The Cura presets for this material show a hot end temp of 205 but I’ve noticed when printing Cura always sets the temp to 210. The quick start guide says PLA shouldn’t exceed 220 so I’m not sure about that suggestion – or why Cura doesn’t use the preset. I’m also not sure if Support perhaps meant I should increase the bed temp. Cura sets that to 60 which I think matches the preset.

Very frustrating to have three picture-perfect prints in a row, then nothing but trouble. That old Cube3D was small, slow, and expensive to operate, but that little bugger just ran flawlessly year after year. I kind of miss it.

Suggestions and advice are greatly appreciated. I have 14 Raspberry Pi camera setups that need a home!

). This site will only allow uploads of pictures. When I change the file extension to a supported picture format and attempt to upload it I get this error:

). This site will only allow uploads of pictures. When I change the file extension to a supported picture format and attempt to upload it I get this error: