I owned the taz 5 for about five months. I absolutely love it and is constantly surprised by the quality of models it produces. This last week the quality has been really inconsistent. The infill layers don’t reach to the outer perimeters and leaves a gap. I also found out that when bridging, it doesn’t reach the otherside before turning back in the other direction. It only does this going from certain directions , right to left. The first thing i tried was to increase the extrusion multiplier and filament diameter that really didn’t help. I then thought it might be that the x axis carriage might be uneven due to being on different threads on the rod. It was uneven but when I started a print it didn’t effect the quality. I leveled the bed. I’m out of ideas , I run everything default on slicer except retraction because after it retracts nothing will come out for a while after so It set 1mm instead of 2. I also get a pitted surface but usually if i slow the speed down to 30mm/s it’s perfect.

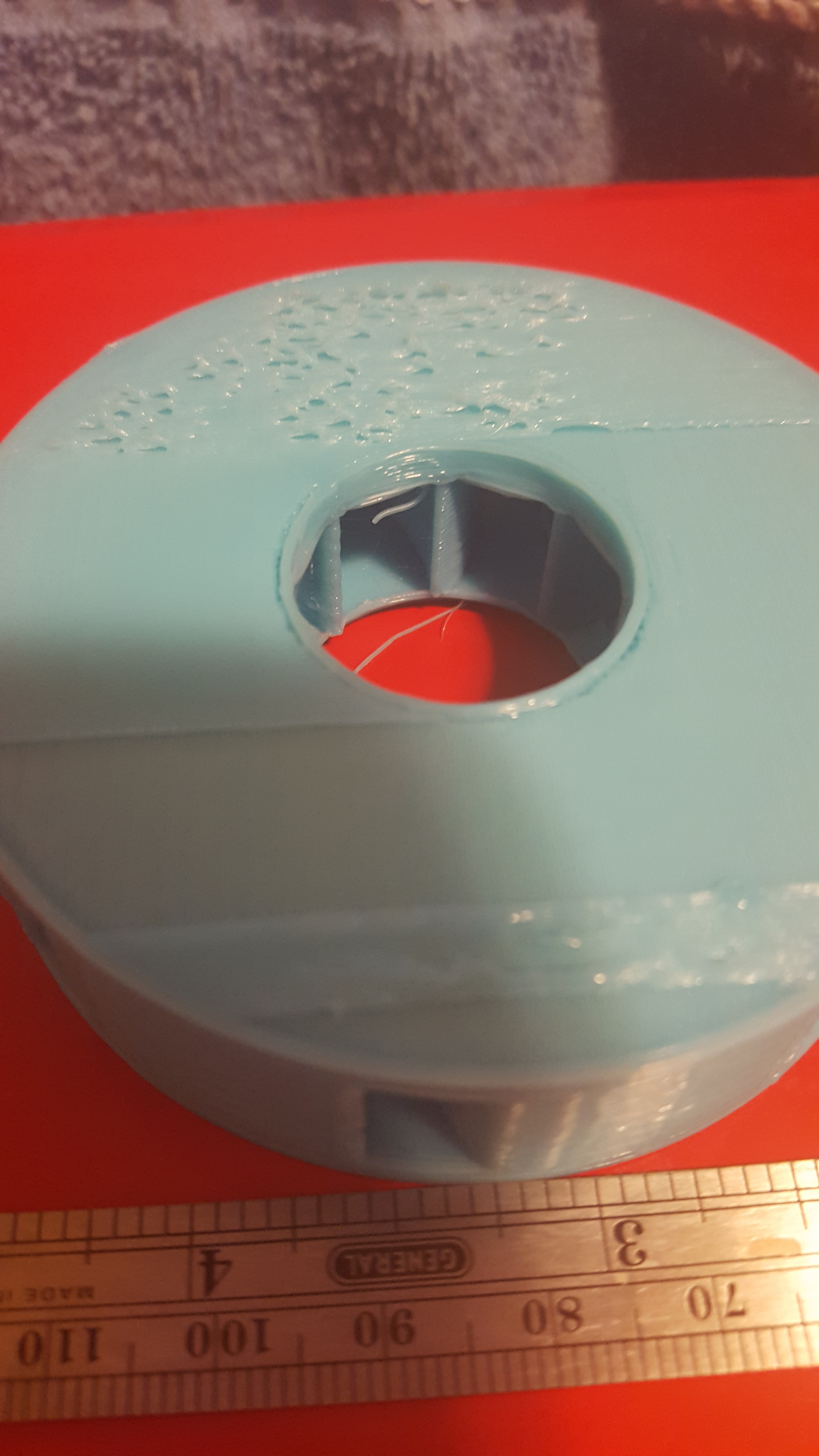

Here’s some pics

We had neary the same problems with our printer at work (Non-Lulzbut, but shouldn’t matter). The extrusion temperature was a little bit to low, in our case I increased it by 10°C and the prints were perfect again.

The first thing i tried was to increase the extrusion multiplier and filament diameter that really didn’t help.

By the way, if you increase extrusion multiplier and increase filament diameter, you may not change anything in reality.

Higher extrusion multiplier = more flow

Higher diameter = less flow (if the diameter of the filament increases, the stepper has to do fewer steps to extrude the same volume of plastic)

Thanks I’m about to give it a go right now I’ll let u know how it goes. My pla temp is already at 210c if increasing it doesn’t help I will try lowering it. I’ll post pics soon. I also have an extra extruder I mostly use for abs, hips, and experimental filaments. I might try switching them out to see if that affects it any.

You are underextruding in those pictures. That’s one of the main causes of those ripply top surface layers. The extrusion bead isn’t thick enough to stick to the underlying layer. Especially if you are printing at a really low infill to begin with.

I tried both of your suggestions but nothing seemed to work so I ended up switching out my extruder. That did the trick now I’m back to the extraordinary quality of the taz 5. I’m going to tear down that extruder and try to find what’s wrong with it then run it at 275c for a while to clear out any gunk. I will probably run some cleaning filament through as well. I don’t know if cleaning the tip with acetone will clear out any pla so I won’t probably do that.