Hi,

I bought a Taz 6 2 months ago, I printed 2 small things then the nozzle clogged, I tried to remove it from the hot end but it broke, so I bought some 1.75 mm hotends from ebay due to the pandemic and lulzbot not making more hotends, I updated the printer firmware (without seeing the Z Height), but changed the new hotend (with a 0.4 mm nozzle) and started to print, I’m using ABS for now, with some minor issues (ozzing and some blobs) but no big deal, until a few days ago, the nozzle clogged, I changed the nozzle with a 0.8 mm (I wanted to speed printing times) and for some reason it would not stick in the bed, I tried with some PVE glue and worked (before I did not use glue).

In the back the nozzle was to close to the bed that the filament was very squished an in the front was ok, I tighten up a little bit the screws of the washers and ran some diagnostics that I read from another post (bed leveling issues) and got the following:

This is with a Probe Z Height of -1.21:

< [10:58:24] G29 Auto Bed Leveling

< [10:58:38] Bed X: -9.000 Y: -9.000 Z: -0.009

< [10:58:52] Bed X: 288.000 Y: -9.000 Z: -0.201

< [10:59:06] Bed X: 288.000 Y: 289.000 Z: -0.212

< [10:59:22] Bed X: -9.000 Y: 289.000 Z: 0.060

< [10:59:22] 4th probe point, distance from plane: 0.08

< [10:59:22]

< [10:59:22] Eqn coefficients: a: -0.00078178 b: 0.00009794 d: 0.00462977

< [10:59:22] Mean of sampled points: -0.09071571

< [10:59:22]

< [10:59:22] Bed Height Topography:

< [10:59:22] ±-- BACK --+

< [10:59:22] | |

< [10:59:22] L | (+) | R

< [10:59:22] E | | I

< [10:59:22] F | (-) N (+) | G

< [10:59:22] T | | H

< [10:59:22] | (-) | T

< [10:59:22] | |

< [10:59:22] O-- FRONT --+

< [10:59:22] (0,0)

< [10:59:22] +0.15084 -0.12166

< [10:59:22] +0.08134 -0.11053

< [10:59:22]

< [10:59:22]

< [10:59:22] Corrected Bed Height vs. Bed Topology:

< [10:59:22] +0.04031 +0.00000

< [10:59:22] +0.00000 +0.04031

< [10:59:22]

< [10:59:22]

< [10:59:22]

< [10:59:22] Bed Level Correction Matrix:

< [10:59:22] +1.000000 +0.000000 -0.000782

< [10:59:22] +0.000000 +1.000000 +0.000098

< [10:59:22] +0.000782 -0.000098 +1.000000

< [10:59:22] X:-9.00 Y:289.00 Z:6.22 E:0.00 Count X:-905 Y:29045 Z:9945

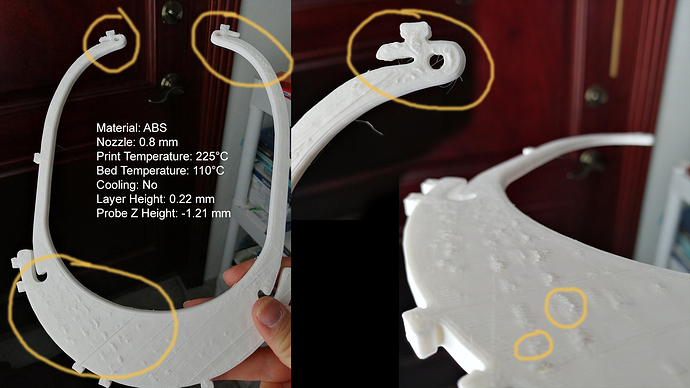

I printed a model with the following settings:

Material: ABS

Nozzle: 0.8 mm

Print Temperature: 225°C

Bed Temperature: 110°C

Cooling: No

Layer Height: 0.22 mm

Probe Z Height: -1.21 mm

This model had some lumps and as the nozzle moved over those lumps, all the hotend moved up and down making a lot of noise. See this pic:

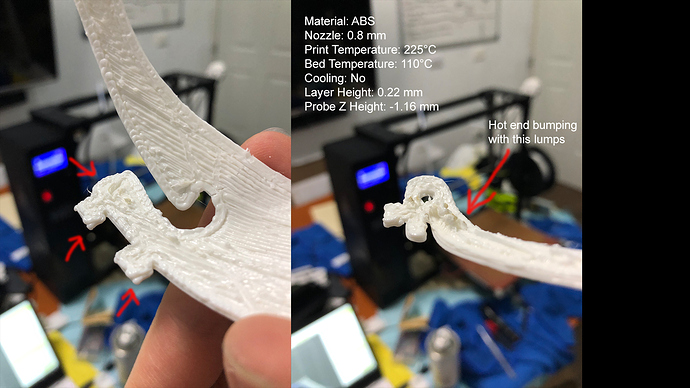

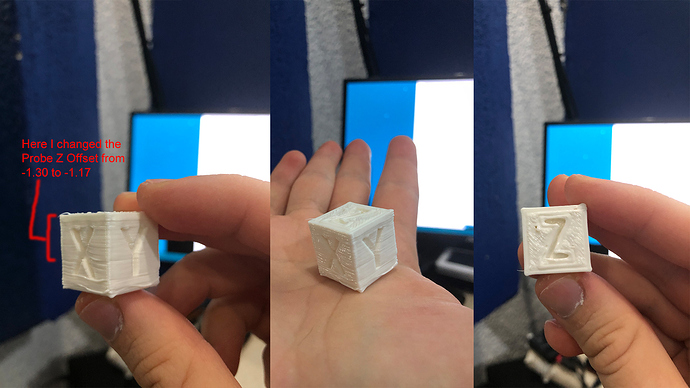

Then I changed the Z Height:

Material: ABS

Nozzle: 0.8 mm

Print Temperature: 225°C

Bed Temperature: 110°C

Cooling: No

Layer Height: 0.22 mm

Probe Z Height: -1.16 mm

The first layer was almost perfect with some lumps in the middle, but after some time it created bigger lumps and the nozzle made more sound as it passed over the lumps, see this pic of the lumps on another post (I aborted the print, that is why is all curly):

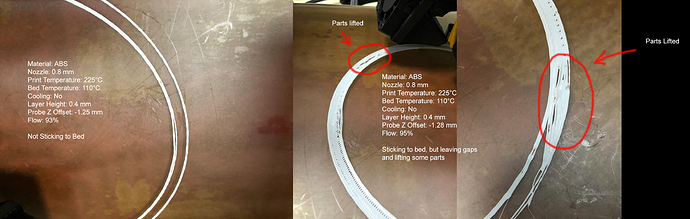

Then I changed the settings in bold:

Material: ABS

Nozzle: 0.8 mm

Print Temperature: 225°C

Bed Temperature: 110°C

Cooling: No

Layer Height: 0.4 mm

Probe Z Height: -1.15 mm

But now the filament is not sticking to the bed, see this video.

This is the bed leveling command with a Probe Z Height of -1.15:

< G28;

< [12:17:12] X:-19.00 Y:258.00 Z:10.00 E:479.09 Count X:-1910 Y:25929 Z:16000

> [12:17:17] G29 V4;

< [12:17:19] G29 Auto Bed Leveling

< [12:17:33] Bed X: -9.000 Y: -9.000 Z: -0.093

< [12:17:47] Bed X: 288.000 Y: -9.000 Z: -0.158

< [12:18:01] Bed X: 288.000 Y: 289.000 Z: -0.215

< [12:18:17] Bed X: -9.000 Y: 289.000 Z: 0.045

< [12:18:17] 4th probe point, distance from plane: 0.20

< [12:18:17]

< [12:18:17] Eqn coefficients: a: -0.00054693 b: 0.00013695 d: -0.04802919

< [12:18:17] Mean of sampled points: -0.10515187

< [12:18:17]

< [12:18:17] Bed Height Topography:

< [12:18:17] +--- BACK --+

< [12:18:17] | |

< [12:18:17] L | (+) | R

< [12:18:17] E | | I

< [12:18:17] F | (-) N (+) | G

< [12:18:17] T | | H

< [12:18:17] | (-) | T

< [12:18:17] | |

< [12:18:17] O-- FRONT --+

< [12:18:17] (0,0)

< [12:18:17] +0.15041 -0.10959

< [12:18:17] +0.01203 -0.05284

< [12:18:17]

< [12:18:17]

< [12:18:17] Corrected Bed Height vs. Bed Topology:

< [12:18:17] +0.09756 +0.00000

< [12:18:17] +0.00000 +0.09756

< [12:18:17]

< [12:18:17]

< [12:18:17]

< [12:18:17] Bed Level Correction Matrix:

< [12:18:17] +1.000000 +0.000000 -0.000547

< [12:18:17] +0.000000 +1.000000 +0.000137

< [12:18:17] +0.000547 -0.000137 +1.000000

< [12:18:17] X:-9.00 Y:289.00 Z:6.17 E:479.09 Count X:-905 Y:29045 Z:9865

It seems that I can’t use a layer height of more than 0.22 mm or a faster speed, I have the initial layer at 15 mm/s and overall speed of 50 mm/s.

I hope you can help me, thanks in advance,

Manuel