As a quick piece of information… I am not trying to print with dual filaments. I have given up that effort for the moment.

The problems I have been experiencing are completely trying to print out of extruder 1 only.

I am printing polylite PLA.

I have experienced this problem since we purchased the Lulzbot Pro last year.

We swapped the print head for the SL print head and were able to use the printer properly… until we had a bad print fail that broke some wires on the print head (working with Lulzbot support to get the proper parts to repair)

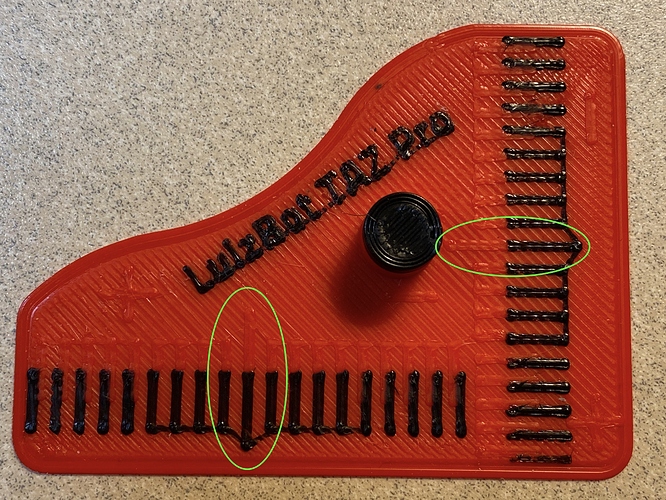

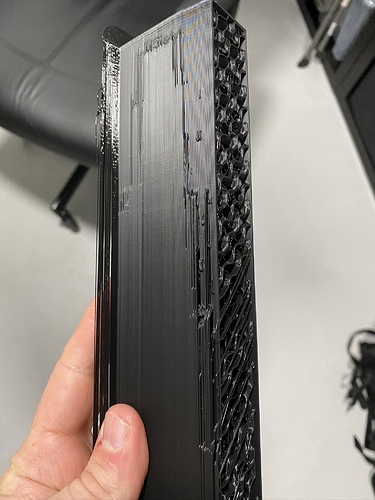

I have not performed any adjustments to the steps/mm yet. When I printed the black cube above last week, the measurements were extremely close, (19.98, 19.95, 19.92). Given the nozzle hitting problem I was having, and Lulzbot support response, I was trying to dial in the Z-offset, which was at the factory set -1.35.

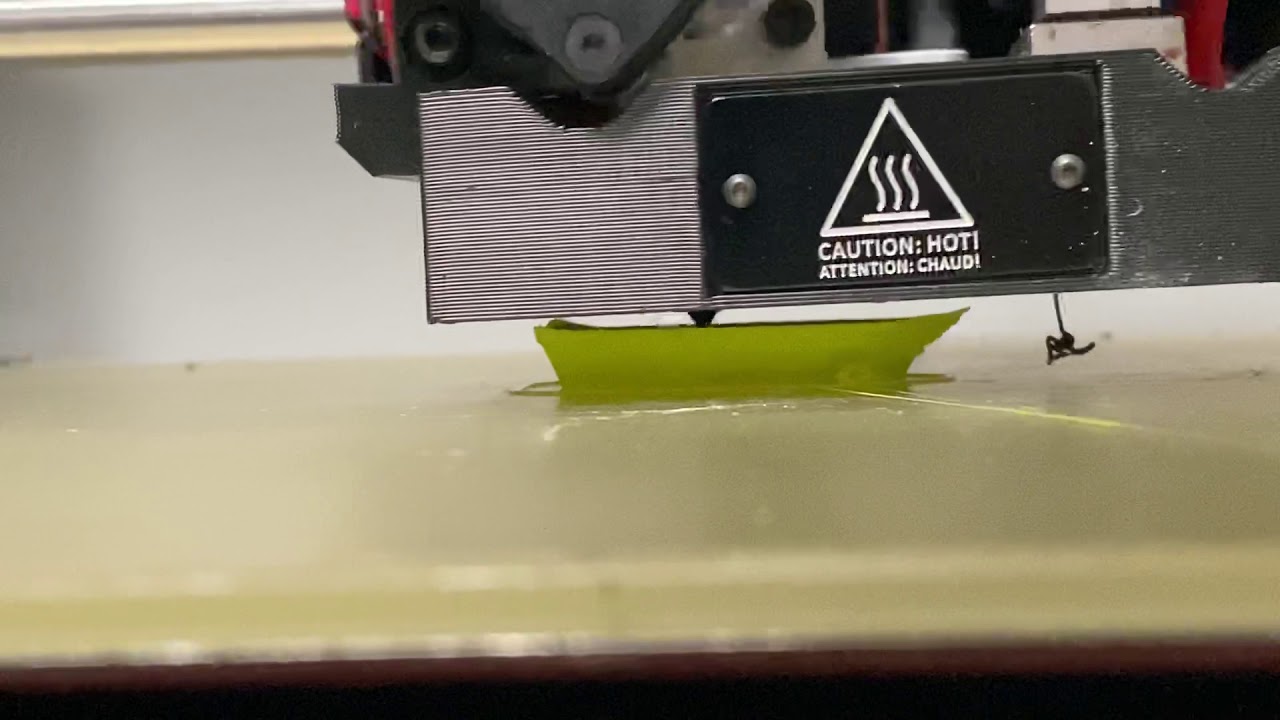

I have printed numerous prints to try and get that dialed in. When the z-offset gets to about -0.9, the filament is too far from the print bed and does not adhere properly. I had adjusted it to -1.0 and was having decently luck with adhesion as well as a decent pattern on the first few layers.

I then printed a large print (14 hours) successfully and kicked off another larger print (22 hours). During that 22 hour print, I could HEAR the print head hitting the gyroid infill pattern when it finished on layer and was traveling back to start the next layer. A few times those ‘hits’ were quite loud.

About 6 hours into the print, I cancelled it because there were a bunch of layers that were obviously shifted. I suspected the nozzle hit the print and skipped a gear and was ‘off’ slightly…

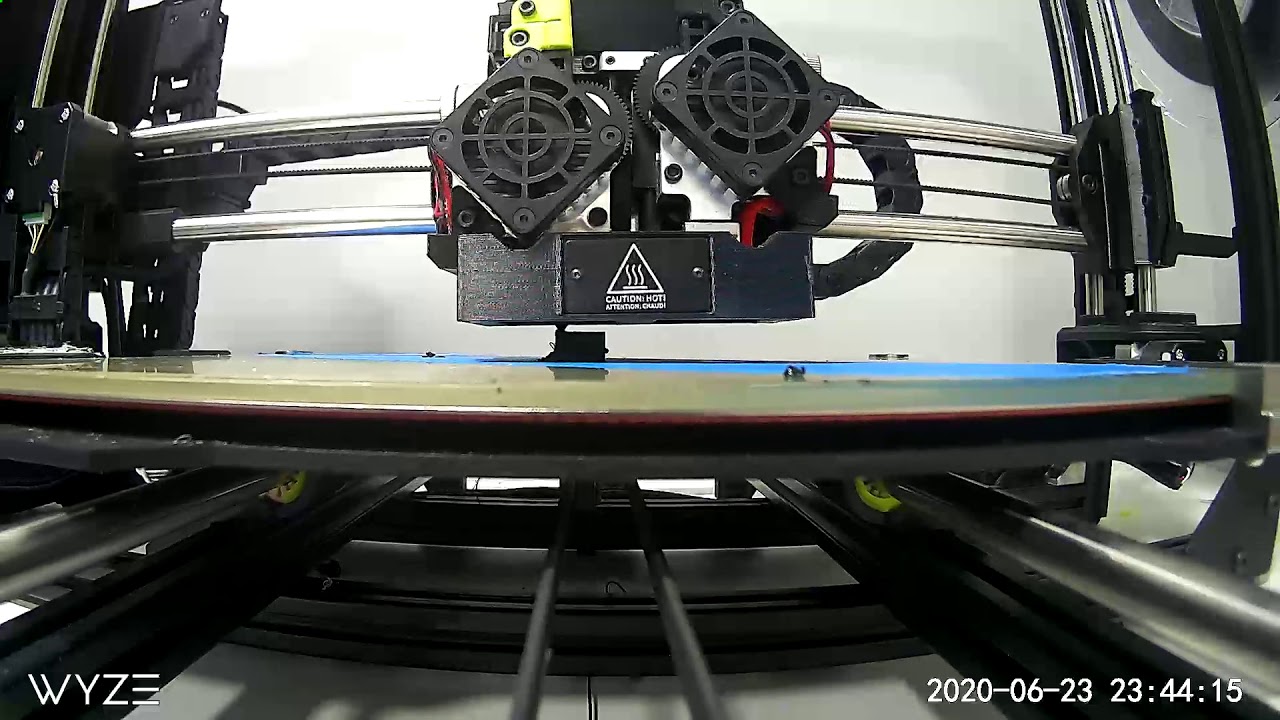

So I attempted to do another auto-calibration (filament removed & nozzle cleaned).

After the auto-calibration, things were MUCH worse.

So I reset the printer to factory settings and tried to print a basic 20mm cube again.

Autolevel failed

I tried again and watched more closely… the nozzle was about 10mm to the left of where it was supposed to be. It was ‘wiping’ in air and then missing the auto level washer altogether… hitting the print bed instead, VERY hard.

So I ran another auto-calibration… then ran another 20mm cube. That is the ‘squished’ cube you see in the photo above and the short (third) video above.

Currently the printer’s steps/mm are set to (I’m assuming) the out of the box

x- 100 steps / mm

y- 100 steps / mm

z- 500 steps / mm

My nozzle offset is (based on auto calibration)

x- 49.29mm

y- -0.16mm

z- -0.48mm

My z-offset is currently -1.20mm

I am going to try and print any other 20mm cube and see what happens.