I want to be able to print sometimes with a single flexible filament only on the flexy head. I dont see even basic support in Cura 21.04 to accomplish this goal. A search thru the forums reveals this is a comman request of flexydually owners. My point is it’s not easy to print with just the flexy. It’s sold to advanced users, I get it. But shouldn’t printing single filaments on the flexydually be part of the Lulzbot edition of Cura? It’s not even in the new beta 2.4.

So I have searched the Lulzbot forums and this post from 2015 helped. But I’m not sure the instructions provided were intended for the Taz 6. Also read some other post’s that said use a single extruder profile for the material you want to print with. So I loaded a single extruder profile but that’s only half the battle. You need custom gcode to handle a few things thats not in the single profiles start gcode.

This is the start gcode I hacked together. Need some help fixing it, or some other suggestions to achieve goal above.

;This profile is designed specifically for LulzBot TAZ6 3D Printer

;Basic slice data:

;Sliced at: {day} {date} {time}

;Layer height: {layer_height}

;Walls: {wall_thickness}

;Fill: {fill_density}

;Estimated Print time: {print_time}

;Filament used: {filament_amount}m {filament_weight}g

;Filament cost: {filament_cost}

G26 ; clear potential 'probe fail' condition

G21 ; set units to Millimetres

M107 ; disable fans

G90 ; absolute positioning

M82 ; set extruder to absolute mode

G92 E0 ; set extruder position to 0

M140 S{print_bed_temperature}; get bed heating up

M104 S170 T0 ; soften filament

M104 S170 T1 ; soften filament

M907 E67 ; set safe extruder torque

G28 XY ; home X and Y

G1 X-19 Y258 F1000 ; move to safe homing position

M109 R170 ; soften filament for z homing

G28 Z ; home Z

M104 S170 ; cool to probing temp during wipe

;T0;

;G1 E-5 F100 ; suck up XXmm of filament

;T1;

G1 E-15 F100 ; suck up XXmm of filament

G1 X-17 Y100 F3000 ; move above wiper pad

G1 Z1 ; push nozzle into wiper

G1 X-19 Y95 F1000 ; slow wipe

G1 X-17 Y90 F1000 ; slow wipe

G1 X-19 Y85 F1000 ; slow wipe

G1 X-17 Y90 F1000 ; slow wipe

G1 X-19 Y80 F1000 ; slow wipe

G1 X-17 Y95 F1000 ; slow wipe

G1 X-19 Y75 F2000 ; fast wipe

G1 X-17 Y85 F2000 ; fast wipe

G1 X-19 Y80 F2000 ; fast wipe

G1 X-17 Y70 F2000 ; fast wipe

G1 X-19 Y75 F2000 ; fast wipe

G1 X-17 Y95 F1000 ; slow wipe

G1 X-19 Y90 F1000 ; slow wipe

G1 X-17 Y85 F1000 ; slow wipe

G1 X-19 Y90 F1000 ; slow wipe

G1 X-17 Y80 F1000 ; slow wipe

G1 X-19 Y95 F1000 ; slow wipe

G1 X-17 Y75 F2000 ; fast wipe

G1 X-19 Y85 F2000 ; fast wipe

G1 X-17 Y80 F2000 ; fast wipe

G1 X-19 Y90 F2000 ; fast wipe

G1 X-17 Y85 F2000 ; fast wipe

G1 Z10 ; raise extruder

G1 X-9 Y-9 ; move above probe

M204 S100 ; set accel for probing

G29 ; probe sequence (for auto-leveling)

M204 S500 ; set accel back to normal

G1 X0 Y0 Z15 F5000 ; get out the way

T0 ; switch 2 extruder 0

M104 S0 ; hotend off turn off extruder 0

G1 Y50 ; move Y to new offset position

G92 Y0 ; set new Y offset

T1 ; activate E1

M400 ; clear buffer

G4 S1 ; pause

M117 Heating... ; LCD status message

M140 S{print_bed_temperature}; get bed heating up

M109 R{print_temperature} ; set extruder temp and wait

M190 R{print_bed_temperature}; get bed temping up during first layer

G1 Z2 E13 F75 ; extrude filament back into nozzle

G92 E0;

M117 TAZ Printing... ; LCD status message

It solves a few problems:

Moves the wipe position up 2mm’s like the dual extruder’s start gcode so the flexydually hotend doesnt hit the wipe pad mount during wiping.

Heat’s up back extruder (T0) before wipe procedure so that filament can be cleaned off during the wiping, allowing a good bed calibration.

After bed autoleveling with T0, turn T0 off so any rigid filament doesn’t cook.

Then move the print head forward 50mm in Y axis and redefine that as your new Y=0 position

G1 Y50 ; move Y to new offset position

G92 Y0 ; set new Y offset

T1 ; activate E1

Then Sets T1 as primary extruder

That basically gets me to where I need to be, printing with just the front flexy extruder. I was able to print the needed gasket alone in ninaflex.

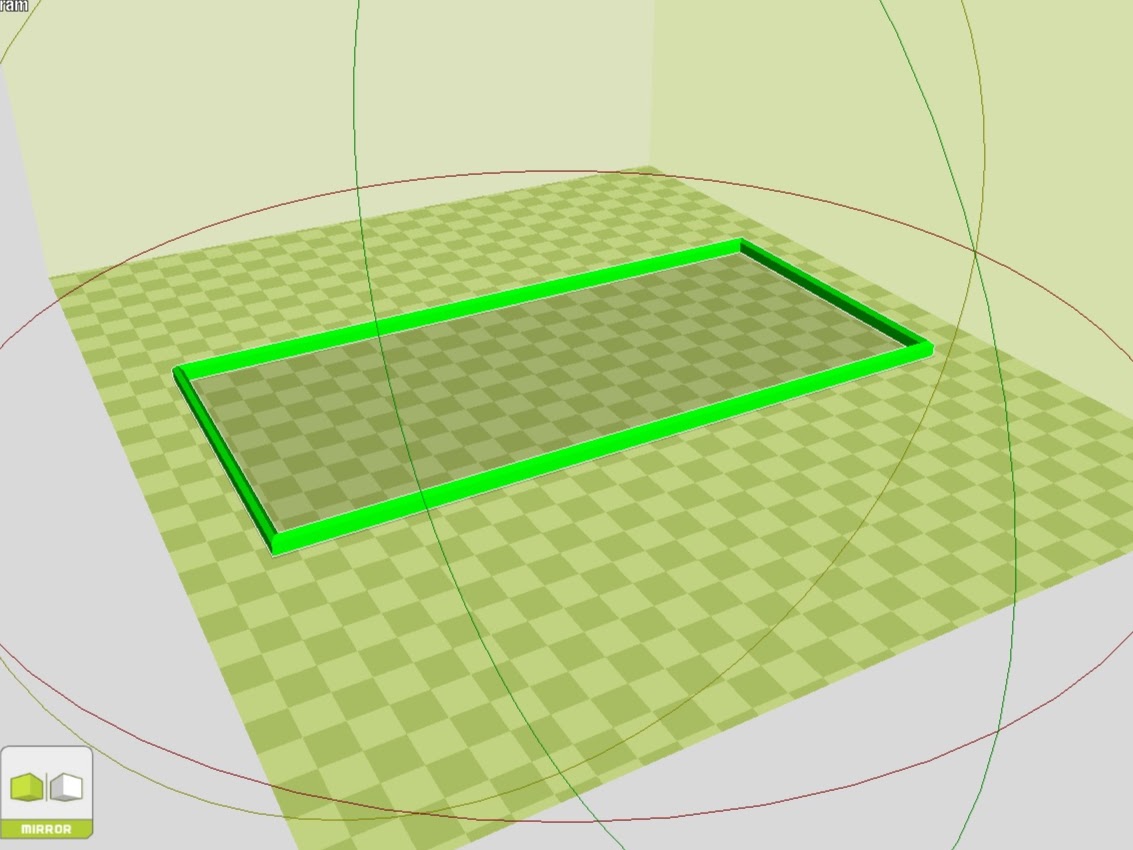

Positioned horizontally in Cura:

Comes out like this:

Already removed 3mm brim in photo but it printed ok, model centered along X however not along Y (ok in this case, but not for a bigger model)

Positioned Vertically in Cura:

Comes out like this:

Sorry long video…

2:20 for change to flexy as primary

3:20 print start

4:45 problems begin

Please help.