Hello,

I’ve recently acquired a Lulzbot Taz 6, but it seems that it needs some fixing up.

When I first assembled it, it was able to move the X, Y, and Z axes, but it would only complete the first two ‘corner touches’ before hanging up. After fiddling with it a bit more, the Z axis no longer wants to move on its own at all, although I can hear it trying to, and when I manually rotate the long vertical screws, the motors seem to be able to rotate both sides with a little extra help.

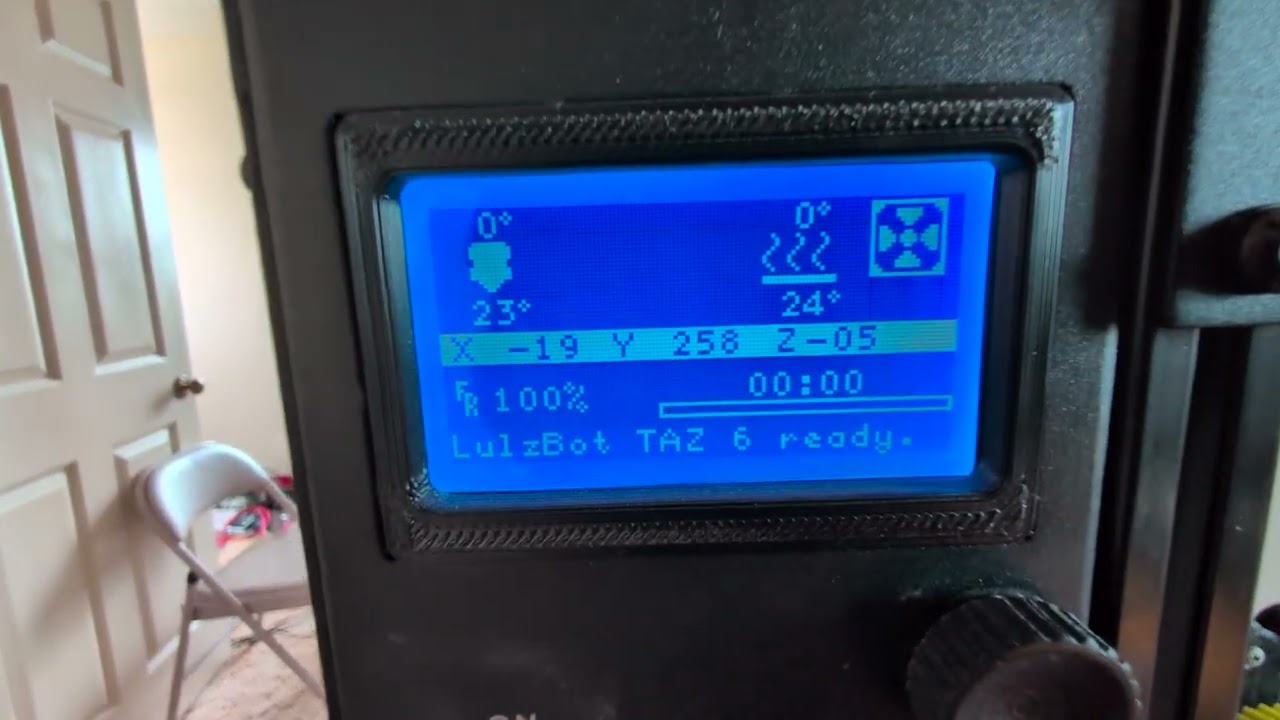

X and Y still move freely, and the bed and extruder heat up fine. I’ve noticed it shows X, Y, and Z coordinates on the LCD, but it doesn’t seem to know where Z is.

I’m not sure what the problem is, or what troubleshooting steps to make next, but I would really love to get this thing up and running, it’s a great machine!

Here’s a video to illustrate what I’ve got going on here: https://youtu.be/bA8ttJ49xeY

I’ve attached some photos that may also help troubleshooting.

Thanks for your help!

A few things:

The nozzle is dirty, which never helps probing the Z.

If it did both sides and stopped, that’s usually the Z gantry isn’t level enough. Use a decent ruler to measure the difference between the z motor to the gantry on both sides. With the machine off, manually twist the threaded rods to get them within 1mm of being equidistant from the motor to the gantry. If they’re very far off from level, there would be too much strain for them to move together and raise/lower the gantry at all with the motor.

If the nozzle was dirty, it would be forcing against the washers, potentially stalling out the motor on the side closer to the toolhead at the time, which is how the gantry can get out of level.

If you level the gantry, and CLEAN THE HECK OUT OF THAT NOZZLE and it still has issues, the threaded rods may be in serious need of some grease (white lithium is a great option). Good to do the clean/lube on them anyway, even if motion is restored.

1 Like

Thanks for your input!

I got some white lithium grease applied liberally to the Z axis drive screws, and I have leveled the z axis multiple times as precisely as I was able to measure. The motor still sounds like it’s trying to move, but won’t go up or down without assistance.

Eventually each attempted print or move to home action I try errors out after a bit of that.

Also the LCD shows a value for X & Y, but shows “??” for Z position.

I tried cleaning the extruder a bit, but it’s caked on there pretty good, I’ll figure that out next

Here’s an updated video:

Z drivers may be toast. Remove the grub screws from the Z axis motor connection to the lead screws to see if both motors can spin freely with no load.

If they move fine without being connected, the driver could still be gone, but if the motors won’t move well without load, consider the Z gone.

Good news is that you can use custom firmware to use the second extruder’s driver to run the Z axis.