I had removed a plugged nozzle, and forgot about this before I had commanded it to go Home. It, of course, could not find a reference, so it smashed into the print bed and reference microswitch button. Now it will not auto-level, and does not appear to have a reference to location. This is an SE print head, and I don’t see a hot-end exterior wire like on the original print head. Thoughts? Help!

I’m going to assume you have the ability to send single gcode commands to the printer over the USB port and see the response. If you can capture the response text and post it here (using the </> icon above) that would help. If you don’t know how to do this, let us know and we can help. The gcode commands below will either have a grey background or are links to the Marlin documentation.

-

Position the nozzle somewhere over the print bed. You can do this manually before you turn the printer on.

-

(Optional) Send an M115 to the printer. Included in the response will be the firmware version.

-

Send an M119 to the printer. The response should be all open. If so, continue.

-

Send G28 X. This should move the tool head to the left and stop immediately. If the tool head doesn’t stop but attempts to keep going, turn the printer off.

-

Send

G28 Y. This should move the bed to the front and stop immediately. If the bed doesn’t stop but attempts to keep going, turn the printer off. -

Send

G28 Z. This should position the nozzle over the switch on the side of the bed and lower the nozzle until it hits the switch and then stop. If the nozzle causes the bed to deflect, turn the printer off. -

Send G29 V4. The V4 parameter produces a lot of output. If the nozzle presses down on any corner causing the bed to flex downward, turn the printer off.

Report back with the results.

Thank you for your timely response. Unfortunately, this is a work printer, and my time spent on it is very limited. I am just now able to revisit.

Also unfortunate are my limited printing abilities. I haven’t been able to find ow to send g-code commands from Google searches/ Is this done through Cura? I apologize for my ignorance.

Thank you for your time!

It depends on what the printer USB cable is connected to but if that is the machine you run Cura on then yes, it is done through Cura. Open Cura and click on “Monitor”. On the right side of the window towards the bottom is an area labeled “Manual control” and under that buttons for Connect, Disconnect, and Console. Click on “Connect” and then click on “Console”. That will bring up a window with a text box at the bottom and a “Send Command” button. Type the commands I outlined and view the results. You may have to check “Show debug messages”.

Hello,

I apologize for the delay. This is a work printer, and at times it is not possible to spend time troubleshooting. I truly appreciate your efforts and patience!

I went through your outlined steps. The G28 steps went fine, but the G29 V4 deflected the bed at the first corner. I have checked for obvious wiring flaws unsuccessfully, but it does seem that there is no communication/connection between the washers and head.

Deflecting the bed at the first corner (or any corner) is usually a sign of either a dirty nozzle (i.e. an insulating layer of filament) or dirty washers. Clean the washers with some alcohol and/or a Scotchbrite pad. Very fine sandpaper (1600 or 3200 grit) will work but be gentle.

The nozzle must first be heated to the high end of the last filament used temperature range. You can go a little higher if you wish. While hot, use a Non-conducting tool (like a Scotchbrite pad to clean the bottom of the nozzle.

It is very tempting to use a brass brush for this step but brass is a conductor and you run the risk of shorting the heater which will either blow a fuse or destroy components on the controller board. However, a brass brush works really well so after heating the nozzle, turn the printer off and brush away at the bottom of the nozzle while it is still hot (I’ve carefully encased the wiring on my tool heads with some high temperature silicone so I can use a brass brush while power is supplied).

Now try the G28 G29 V4 steps again and see if it works. If it does not, then there may be a loose wire somewhere and we will need to troubleshoot that next. You will need a multimeter so if you don’t have one, its a very useful tool to have.

It sounds like the zero sense line on your print head may have been disconnected or damaged, when you removed the plugged nozzle.

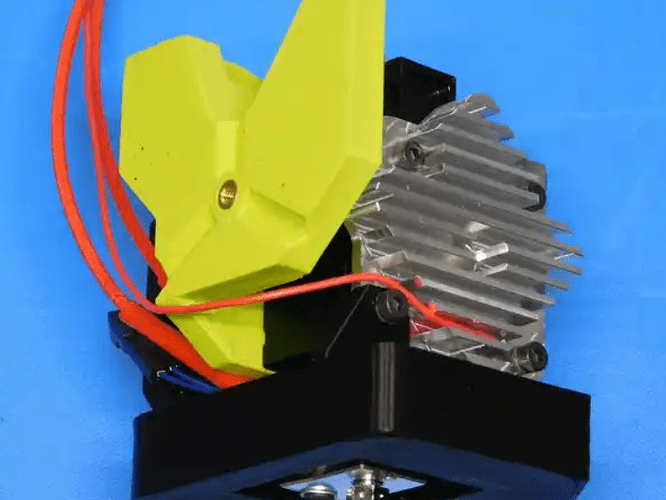

The zero sense line should be clearly visible along the bottom of the SE toolhead’s heatbreak heatsink:

When the toolhead starts moving down toward the first washer, use an extra length of wire to contact the washer and the ring terminal that holds the sense wire to the heat sink. If it does not immediately stop moving, turn off the printer to prevent crashing. If it does stop, your connection between the nozzle and sense wire is faulty. Check assembly of the SE toolhead - https://ohai.lulzbot.com/project/lulzbot-mini-2-aerostruder-assembly-and-packaging/hot-end-tool-head-assembly/

If it didn’t stop, now power it back up, and this time use your wire to connect the washer directly to pin #8 of the harness.

If that also fails to stop the movement when it goes for the first washer, it’s either in the bed’s zero sense connection or the board has issues.

Thank you for your response, Wrathernaut. As an electrician, I suspected this might be the case, but didn’t know the details on which wire was used for this. I purchased a new toolhead for this reason. You can imagine my disappointment when this didn’t correct the problem. I checked this wire on both toolheads, and they are in good shape.

A friend had suggested the Z-axis may be off. I wish I had written down what the value of the Z offset was before I adjusted it, but I believe it was around 129! This didn’t seem like it would be right, so I zeroed it out, and have been adjusting a little at a time. It seems to work pretty well at -.9. At any rate, I am much closer to printing now! But the prints are still failing as shown:

Any ideas? I tried using the suggested settings in Cura to no avail…

That last image looks significantly overextruded. Did you select the correct toolhead from the printer’s menu? If so, do that. If it is the correct toolhead selected, you definitely do a E-step calibration, and make sure you save the settings in the menu, otherwise they don’t stick.

Once esteps are correct, make sure your flow isn’t set above 100% anywhere.

You nailed it, Wrathernaut! I had neglected to realize that when I updated the bios, I needed to select the printer head again. Thank you so much!