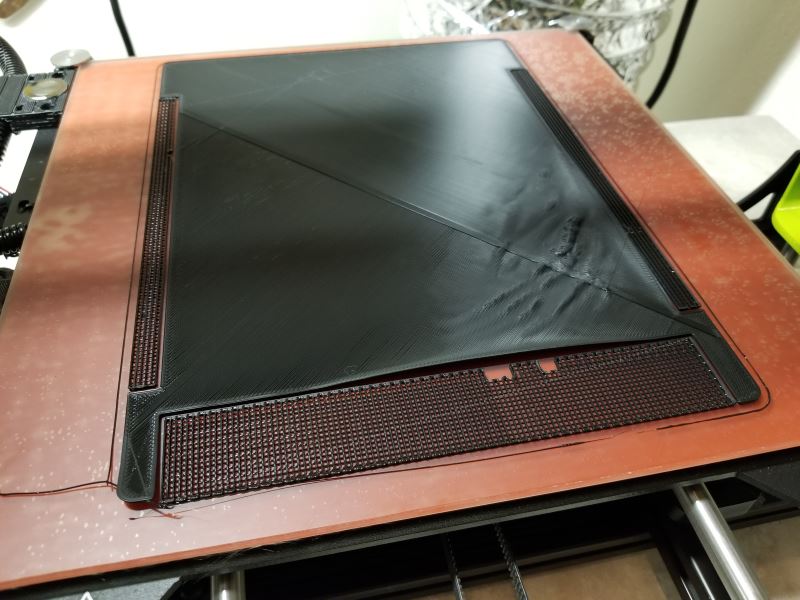

I was trying to print a large box on my Taz 6. I am using the Inland PLA from Micro Center with the Polylite for the material selection in Cura. The front right section lifted off the print bed while the rest of the print seemed to lay flat. What causes this? I did not apply anything to the print bed before starting.

Is there an issue with the print bed not being uniformly hot? Should I apply the PVA glue before printing? The print came off the bed very easily and smaller thin pieces come loose occasionally during the print process.

Well, lots of things cause warping…The warping is caused by the contraction of the plastic as the filament cools. When the edges lift from the plate, cool air seeps under the print. So it could be oils on the PEI, unlevel bed, cold drafts…

Typically it happens at the corners, but could very well lift on any edge. Check that the PEI is clean, a little alcohol will clean of any oils from your hands.

Try using a 5-10 perimeter BRIM to help seal the edge… and even if air gets under the print, the brim acts as a buffer to the print.

Or add flat anchor discs at each corner to hold them down. Something like a .3 to .5 thickness shape is easy to remove with minimal post-processing cleanup.

Hmm. CURA won’t let me add a brim. I suspect because the print size takes up too much of the bed. I’ve cleaned up the bed with alcohol and made sure the z-axis is level. The room is pretty small so little chance of drafts. Room temp is 67 F (19C), Bed temp is 60 C and Nozzle is 205 C. The last attempt the lifting happened within the print (not perimeter) and looks like “fish gills”

How many layers have been printed when the problem occurs?

I’d try raising the bed temperature to 70C and probably increasing the first layer thickness. If the problem occurs on the second layer, lower the speed of the cooling fan or don’t turn it on until a higher layer.

You can lower the bed temperature down after a couple of layers.

If it is drafts, fashion an enclosure. Google will find some homemade ideas. I’d try some poster paper I could bend into a semi-circle and tape as a temporary solution.

Maybe 3-4 ? That’s by the time I noticed it. It could have started first layer. I’ll try raising the bed temp to 70 for a few layers until it looks solid and then drop it back to 60. Thanks!

I did raise the temp, however it went back to 60 on its own. Does the temp setting get sent every z layer?

How did you raise the temperature? If it was from the LCD, it will get reset by commands in the gcode file.

You need to either change the temperature in CuraLE and reslice or edit the gcode (look for M104 S60, M104 R60, M109 S60, and M109 R60 and change 60 to 70).

CuraLE let’s you set the initial layer temperature and the rest of the layers temperature so that’s probably the easiest way to change it and then reslice.

Yes I did it through the LCD. I will retry with CURA. Thanks for your help!

I ran a few tests with the bed temperature. First I ran at 70 C which caused the PLA to clump together and not stick down at all. I then tried the temp at 65 which worked well for the front of the bed, however the back of the bed clumped up like it was too hot. I will test again with 62, but it seems like the bed does not have an even temperature across the entire surface. The room is small and enclosed so there aren’t drafts.

It’s hard to tell but the poor bed adhesion when you upped your bed temperatures might be because your z-offset is a little too high. I am attaching a photo of what a good first layer will look like for you to use as reference to see if yours needs to be adjusted. (I am basing this off of the line of filament from your “Skirt” in the photo in your very first post in case you were curious)

Always make small adjustments to your z-offset and keep an eye on it during the first print after an adjustment to avoid running your nozzle into the print bed and damaging the PEI surface.

You may be on to something. I DID modify the z-axis to make sure the distance between the two columns was the same (as close as I could measure) and ever since that point I’ve had issues. I thought that if I got the z-axis the same distance , then the auto-leveling would make everything perfect. The different bed temperatures have not corrected the problem.

I did expect that the auto-leveling would set the z-height appropriately without requiring adjustment.

Auto-leveling just ensures that the z-height is the same from corner to corner, referenced from the top of the bed washer (where the probe touches). One would think that it’d be possible to calculate the top of the bed from that – the z-offset would be the thickness of the washer in that case. But it doesn’t work quite so simply – I suspect the washers may be slightly different in thickness from production run to run, or more likely, the PEI and adhesive layer is compressed differently, and thus you get to adjust for that…

I dropped the bed temp back down to 60 C and then slightly lowered both z axis by maybe one-quarter turn downward. I started the print again at 10 am and at 3pm it has about 1/3 inch built up and no warping at all. I appreciate the assistance in figuring out the issue!