Hello All,

I purchased a NOS Dual Extruder V3 and, after removing the original filament from factory testing, proceeded to modify it to run 1.75mm filament.

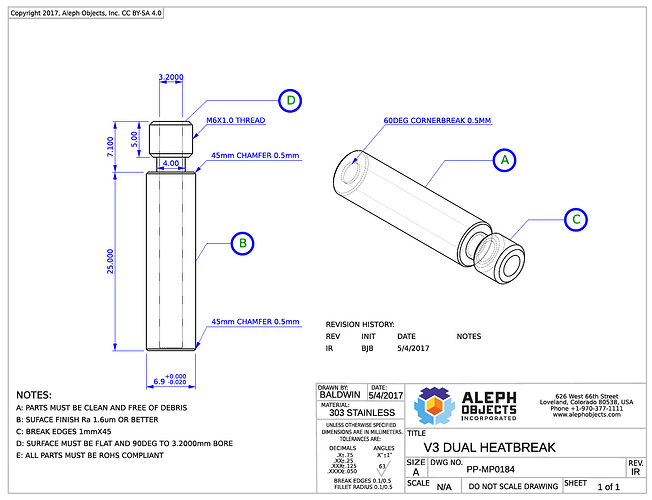

This included making 2 new stainless steel heat breaks, reducing the ID of the filament path to 2mm and reducing the heat break OD from 4mm to 3mm. (photo attached) These are the only parts that needed to be fabricated from scratch.

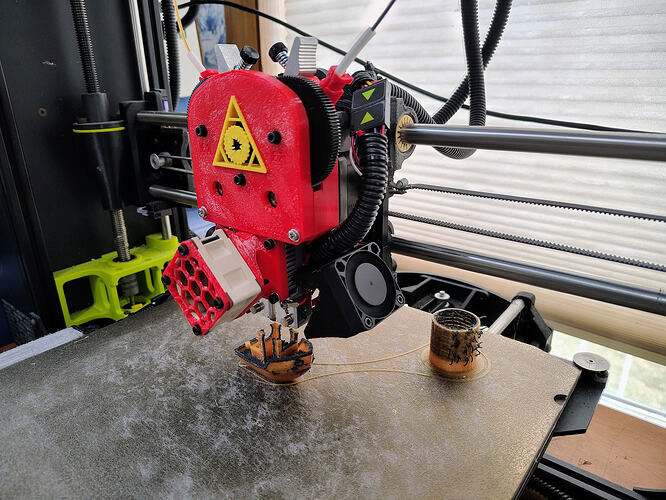

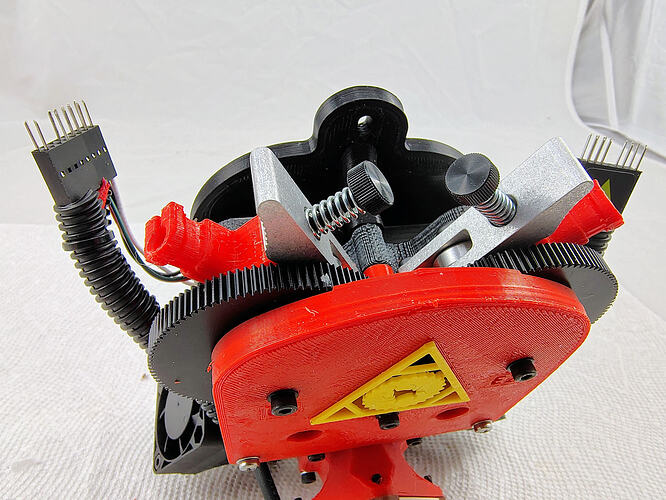

I converted the STEP file (from Github) for the mid-plate to TurboCAD and then reworked and resized the filament paths to accomodate the smaller diameter filament (reducing the diameter and moving the inlet closer to the hobbed gear). The filament path is now lined with a 3mm OD / 2mm ID PTFE tube from the inlet at the hobbed gear to the top of the heat break. This should work better than a 2mm teardrop-shaped pathway. I also added “ears” for 4mm OD / 2mm ID tubes at the top of the plate to facilitate filament loading and to provide a secure anchoring for a “reverse Bowden” tube if desired (This should work great with filament fed from the standard, TAZ side-hung spools or for moisture-sensitive filament (i.e. PVA) fed from a dry box). The new plate is printed in PCTG rather than the original ABS. (STL file attached)

The print head had the original front bearing plate, missing two screws at the bottom corners. This was replaced with the V0.2 version available on Github. It was also printed in PCTG to match the mid plate. (STL file attached)

While I was dressing things up, I worked up a logo insert for the front bearing plate. This should be printed with a 0.25mm nozzle. Some detail was lost with a 0.4mm. (STL file attached) The insert was derived from a Lulzbot 40mm fan cover located on Github.

Cooling was improved with a Noctua 5V 40x40x20 fan and a fan housing recommended by another forum post addressing early cooling issues. ( Fan Duct for - LulzBot TAZ Dual Extruder V3 Tool Head by mordiev - Thingiverse ) Repeated Fails T6 dual extruder recently

I added a fan guard to help protect the Noctua fan and my grandkids’ curious fingers. ![]() 40mm Fan Cover Honeycomb by pakkko - Thingiverse

40mm Fan Cover Honeycomb by pakkko - Thingiverse

PP-GP0291_Bearing_Housing_front__v0-2.STL (841.5 KB)

some_struder_dual_plate-1.75mm Lined Path w Ears.STL (2.7 MB)

LulzBot_Logo Insert for Dual Extruder V3.STL (1.6 MB)

The result so far is that the new head works great. I’ve printed several larger (12 hour+) prints in PLA/PLA (2 color) and PLA w/ PCTG supports with no issues. Next on the list to try is PVA disolvable supports.

This has been a fun and rewarding side project. Hopefully it can be of some benefit to others.

Enjoy!

Todd.

Todd Snouffer

Littlelocos Model Engineering

Hagerstown, MD