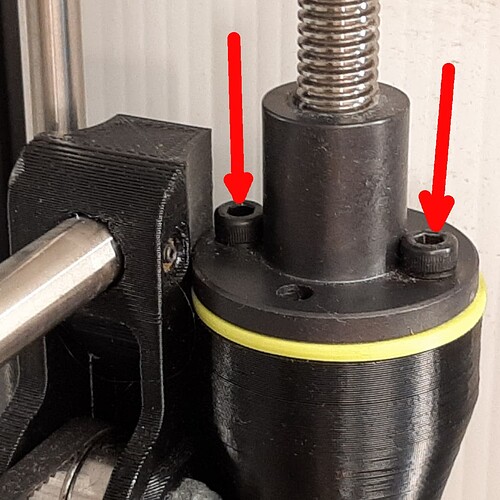

Here is an image with the screws for the right hand Z-nut indicated. The top smooth rod of the X-axis is on the left of the image and the flexy washer can be seen under the Z-nut.

I found the Lulzbot instructions for the final assembly of the TAZ 6.

https://ohai.lulzbot.com/project/taz-6-final-assembly/taz-6/

In Part 6 - Adjust Z-Axis, they describe how to adjust the screws holding the Z-nuts to the Z-carriage. Frankly, the description leaves a lot to the imagination but it is a good place to start.

Lulzbot uses the phrase “tight but not too tight” (TBNTT) when describing tightening the screws that fasten the Z-nut to the Z-carriage. If a Z lead screw is slightly bent, the Z-nut needs to be able to “wobble” a bit in order follow the bend and not bind. The flexy washer and the “not too tight” screws allow a bit of wobble to occur but getting to the “TBNTT” condition is tricky. I’ll describe how I go about it.

Safety First - Remove rings and jewellery, roll up your sleeves and keep long hair tied back. This will involve getting very close to the rotating Z lead screws, so keep your wits about you.

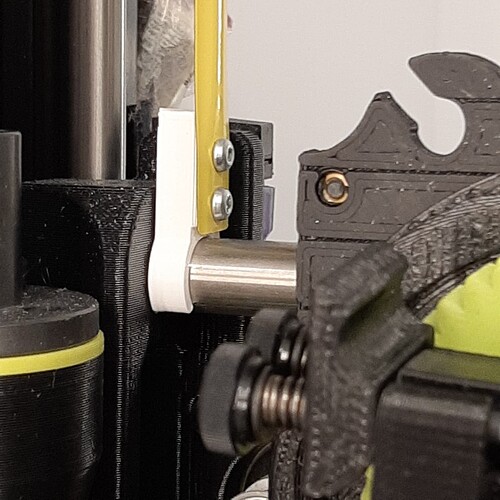

You’ll need a 4mm ball head hex wrench to adjust the M5 screws used to hold the Z-nuts to the Z-carriage.

Make sure your X-axis is level with the bed before starting.

https://ohai.lulzbot.com/project/leveling-x-axis/maintenance-repairs/

Use a tooth brush and paper towels to clean the lead screws and smooth rods. If you have already tried lithium grease, try to remove it. We want to get things as close to perfect as we can without lubrication.

Do an Auto Home, then move the print head to the middle of the X-axis. Tighten the M5 screws holding the Z-nuts until they are finger tight and then slowly loosen them until you can rotate the Z-axis lead screw easily by hand. Now run the print head up to the top of the Z-axis in 20mm increments. If you find a spot where there is grinding, go back and forth over it and adjust the Z-nut screws until the grinding goes away. Continue on up the Z-axis making adjustments as required.

I found that it was most effective if adjustments were made while the Z-axis was in motion. This gives you immediate feedback on whether you are turning the screws in the right direction and when you have turned them enough… You will need to leave the ball head of the hex wrench engaged with the screw while doing this, which is tricky near the top of the Z travel.

When you get to the top of the Z travel, repeat the process going back down. This process can take hours, so take breaks.

I also found that where the print head is positioned has an effect on making the adjustments, so check and see if it is true for your machine.

When you get it as good as you can, then try some lithium grease.

Good Luck