I bought a Taz 6 about 5 years ago. It appears over the last several years 1.75 filament is gaining traction as the size to use. Can I use 1.75 in my 2.85 tool head? and would that be a wise thing to do? I really don’t print a lot and I want less headaches. Is 1.75 filament easier to work with as well?

Thank you

Gary

Gaining traction is putting it lightly.

Trying 1.75mm in an unmodified taz6 toolhead is asking for a headache.

You can throw a little bit of 1.75mm PTFE tubing in the Wade extruder to fill in the gap or print a modified version, then replace the hexagon hot end with a 1.75mm V6 style hot end.

Or buy a new toolhead. There’s options from about $60 to $375 depending on how much work you want to do.

Thank you! I guess I would buy a new toolhead when the time comes. After I posted this, I went and counted how many 2.85 spools I currently have. 42! I’ll have to work through that before I move on to 1.75.

My last question though? Should I do that? I don’t really know why I need the 2.85.

42 spools is worth keeping the 2.85mm toolhead around for.

That’s quite a stock for “I really don’t print a lot”.

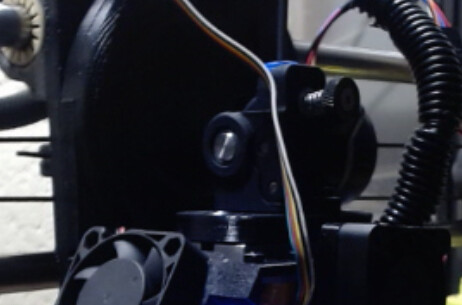

But if you have issues with 2.85mm filament on the Wade extruder, I can personally attest to the massive improvement swapping the Wade extruder up top for a 2.85mm Orbiter extruder. One little adapter

Flexorbiter Adapter v1.stl (4.3 MB)

and about $60 for the extruder, some wire splicing… and you’re good to go:

A nice benefit to the Taz 6 is that the toolheads are easily swapped. If you’re running the latest universal firmware build, it’s about a 2-minute procedure with no firmware changes required.

1.75mm is better for just about every filament, the exception being flexible filaments. 2.85 is still great to have since you have a big supply, and also clearance 2.85mm filament can get you some great stuff at significant discounts.

Yes, I’ve swapped out toolheads for various reasons.

and my wife is a teacher so I print little trinkets for her kids as rewards. this requires just about every color under the sun! I’ll have to research that Wade extruder deal. Not familiar yet with that. Thank you again.

I’d buy an M175 v2 (and a universal adapter). There is support in the Universal Firmware TAZ 6 version. Switching between the stock Single Extruder and the M175 is easily done from the LCD panel.

I recently finished upgrading my Taz6 V2.0 dual extruder from 2.85 to 1.75mm and haven’t looked back. For a drop-in hot end replacement, IT Works 3D has a 1.75mm hexagon hot end for $30. (HEXAGON HOTEND ASSEMBLY - IT-Works 3D) A short length of teflon tubing necks down the original ABS parts to 1.75mm.

That, coupled with upgrading the hot end cooling fans completely got rid of the PLA heat creep issue.

I also redesigned the part cooling fan shroud to allow the fans a much larger area of influence. This fixed the problem I was having with overhangs not cooling properly.

Have fun!

Todd.

I’ve always pulled off 1.75 filament better on my aerostruder than the single extruder without modification, but I have to take it apart a lot. Boy the whole oversized filament moment was way off. Now my Aerostruder needs a new heat chord. I’m going to try this idler mod and tubing to see if it helps the single extruder. Lulzbot Idler Block for 1.75 mm by MosaicResources - Thingiverse

Thanks for posting this print and idea. The orbiter has a sensor wire for bltouch? Your taz does a auto leveling process with this?

The orbiter doesn’t have a thing to do with bltouch, that’s all on how you build your tool head. My 2.85mm tool head of choice on my taz6 has a bltouch mount, orbiter extruder, 5015 blower for part cooling and an original hexagon hot end. For 1.75, I run a biqu h2.

Thanks for the parts breakdown I couldn’t see everything from the photo. I will also research the biqu h2. I bought an ed3 v6 hot end with tube, but haven’t found the right mod out there to use it so I might return it. What cura printer profile do you end up running the flexstruder?

Try a M175v2 that is my recommendation

*update i might have gotten the H175 v2 mixed with the m175