I’ve had the taz sidekick 747 since early September. I immediately had issues with the bltouch out of the box. I got that fixed by just doing a lot of self testing. I was able to print two sample prints with the stl file that cam on the sd card. After that, nothing.

I still have issues with bltouch on and off. I just cleaned and adjusted set screw. It works for now.

I’ve reset settings, upgraded firmware and I still have issues. I have tried other models off thingiverse…I download the stl file, resave in cura, then try printing. Nothing seems to work.

Am I doing something wrong? Can someone help me start over and troubleshoot from scratch? Surely it can’t be this hard to print fresh out of the box?

I only have mac and Lulzbot has only released the latest version of the software to windows only so I’m using a workaround given by support to use it on mac.

1 Like

Hey Jason. I too am only MacOS and have had the machine since this fall. My BL Touch stuck but has been working perfect since. Lulzbot Cura is buggy but I have had much better results recently with PrusaSlicer and Slic3r. There is a Facebook group for the Sidekick machines that has been super helpful as well, including a PrusaSlicer profile from Stephen that is amazing. PrusaSlicer is really tough with supports and rafts for dialing in. I have been told there is a new Lulzbot Cura coming very soon as well which is good news.

Hang in there! Definitely reach out to support (they are great) if you need it I hope to see you in the Facebook group so that we can all give each other a hand. I am a noob, but the 747 is running awesome for me and can for you as well.

I have been struggling for over 8 months to get my Sidekick 747 to work. My latest problem is any print larger than 6cm x 6cm will fail immediately. Only part of the skirt adheres to the base plate and it just gets worse once the actual object tries to print. I do not like the support. Everything is via email and takes forever. If it wasn’t a huge PITA I would ship it back and buy from a different mfg. As an example of bad their support: I told them I was on firmware 2.0.6.6 and I was told to upgrade. After I ran the upgrade it was still 2.0.6.6. Just another waste of my time with Lulzbot support

1 Like

Firmware updates come through the Cura LulzBot Edition software … but this doesn’t automatically download latest firmware. The firmware is included in the download. You should update Cura, then use the latest version to update the printer firmware.

I have had the same issue. The auto level is actually ruining prints - you can’t print anything big because it auto levels above the bed surface on one side.

I think this is a firmware issue. I have been over most of the printer with a caliper testing square etc. and it is pretty good.

They told me I have to ship it back too - $75 for all the original packaging stuff. This is in my classroom - I can’t get my school to pay for it. I shelled out the extra $1000 for a lulzbot so I didn’t have to deal with these issues.

Hello, I believe I was speaking with you through our support ticket. In the examples you had sent us, we did not see any extreme changes on your bed level from side to side. Mainly offset issues and potential filament specific issues.

We are more than happy to bring your printer in under warranty and assess if there is anything out of ordinary, however we do require items to come in original packaging as we have seen a lot of extremely damaged printers because of improperly packaged printers. Damage due to improperly packaged printers are not warrantable.

We always recommend users keeping their packaging as replacement packaging does run $75 as indicated by the sticker on the inside of the packaging itself.

Yes I should have kept better care of the original packaging. I kept all the orange pieces to pack the printer but one of my students grabbed the cardboard box (it was a wonderful 3ply cardboard which is hard to find) and lasercut somethign awesome out of it. I did fix the problem and I will post it below.

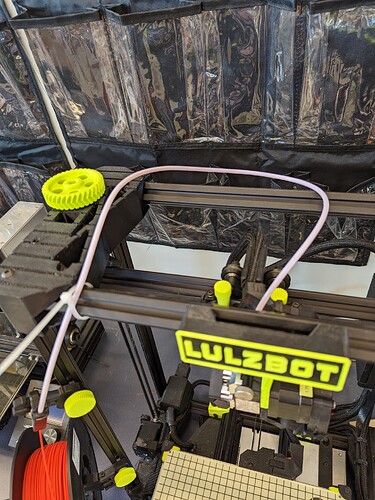

Some of the default movements to max z and -x direction caused the filament guide tube to wrap around the left side belt tensioner. Then when the printer would would print - the aut level would be accurate because the BL touch is on the back of the extruder and would not get pulled, but when the printer went to print the tension of the tube would increase only as it approached the +x axis lifting the nozzle up slightly. There is a strange amount of “wiggle” in the toolhead - it seems very easy to raise up and down compared to the TAZ5, and 6. I suppose this is because it is on V wheels on a single piece of extrusion. You can see in the two pictures how one is wrapped around the belt tensioner. I would often unwrap it but some part of the homing/ startup process would rewrap it - I have found that a zip tie will keep it from getting wrapped again.

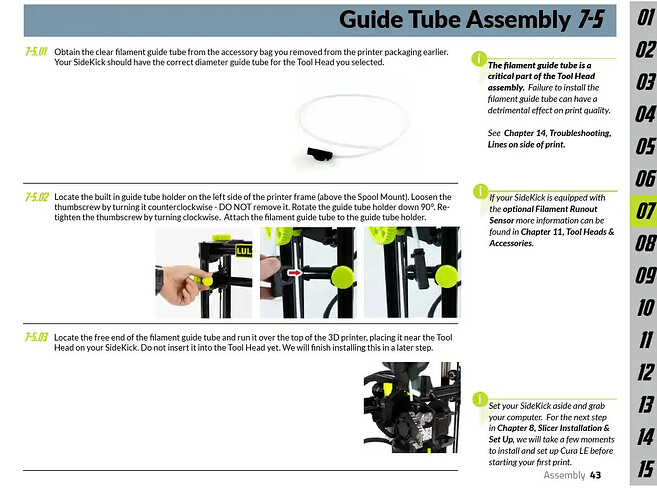

Your tube routing path looks a bit off from what LulzBot shows:

But the routing of that tube is not part of the user manual:

So, it’s a bit of a shortcoming in the manual if this part is unclear and leads to failure. At how infrequently those tensioners should need to be adjusted, it’s a bad design to have it protrude so much without a slope that encourages the tube to slide over it easily.

Yea the tube routing path shown in the picture you have posted is what caused the problems.

because the z toolhead parks at the top of the printer all the slack comes over that belt tensioner and it will get stuck around it.

Because the autolevel prove and nozzle are like a lever this caused the autolevel to be only slightly off while the nozle was pulled high enough that it would not get adhesion on the right side of the build plate.

1 Like