I recently inherited support for our two Taz printers, one being a Taz 6. It does not auto-home properly, failing consistently on the first washer. I’ve checked x-axis alignment (Step 23) and have cleaned both the washers and the head. There is something I’d like to check with the community, however, since I think end users might have tried to monkey with this printer.

I’ve been trying to figure out from video pictures where the 5v sensor for auto homing connected to the print nozzle. I screen grabbed this image:

Seems like the 5V sensor attaches via a screw on the opposite side of the power cables?

On our printer, on the right side of the nozzle (from front) there are two red power connectors and a black cable that goes somewhere…

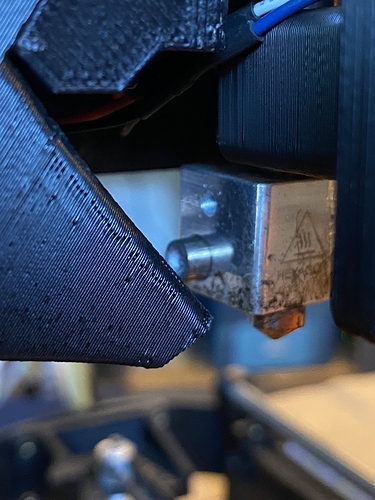

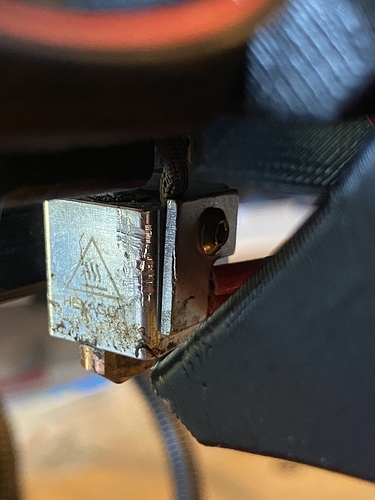

On the other side, where I believe the 5v sensor attaches, I’ve got an empty screw receptacle above and slightly forward of a metal protrusion.

I’ve scoured the wires coming from the extruder cable set and can’t find a free cable in the set. I’m wondering if someone before me put the wrong cable in the wrong place? I’ve removed the right side fan, airflow cage, and then loosened the clamp near the power connectors, but that black cable looks like it goes right into the nozzle and might be in the right place (GND?).

I wonder if my 5v sensor is not attached, therefore it can not auto-home?

Thanks for the assistance. Coming up to speed on this printer as fast as I can. I have pictures of my nozzle but can’t upload because I’m a new user.

I think the wire in the black cable is your thermistor. Does it heat up? The Temperature rise? If so, you have a thermistor and it’s good. Looks like the wire you’re missing is the sensor wire. It should be a red wire with a round terminal attached to it which the screw you’re missing would go through attaching to the heater block.

Yeah, I heat up, extrude, and transit properly, just can’t auto probe. I’ll go back and check for the 5v sensor line that appears to be not attached. I definitely don’t see a round terminal connector dangling about

I wonder if that’s the older version of the hexagon hotend that shipped with the Taz-5 (which didn’t have auto-leveling, thus didn’t need the extra wire). It’s easy to add – the information on assembly of the extruders and hot-ends on https://ohai.lulzbot.com/ can be useful. I’ve built a bunch of extruders for the Taz and Mini, the hardest part is attaching the pins to the wires for the main extruder connector.

The heat block on the Hexagon hot-end has a couple of holes on the sides. One for the heater cartridge and another for the thermistor. Both of these have a pair of wires. The zero-sense wire uses continuity to test when the extruder nozzle touches a metal bed washer … and that’s just a single wire on the extruder (the other wire is attached to the bed).

Here’s a video that shows the assembly of a Hexagon hot-end.

Note that this video doesn’t show the zero-sense wire … but it does show the heater-cartridge and thermistor so, by process of elimination, you’ll be able to work out which wire is your zero-sense wire used for bed-level.

Grab a multi-meter and test that continuity from that zero-sense wire to the tip of the extruder nozzle has a good reading (less than 1Ω resistance). You also want to check the bed washers. There’s another wire attached to the underside of the bed. But since the base of the bed is metal, all washers are conductively attached to the metal plate (via the screw) and the plate is connected to the wire. This means you can test each washer but putting your multi-meter probes on any two washers to make sure you also read less than 1Ω.

If all that checks out well… then test continuity from the sense wires back to the board.

I DO see what looks like filament creeping out of the heat-brake (gap between the heater-block and the cold-side of the extruder.) This happens if the extruder nozzle wasn’t properly seated to “kiss” the threaded end of the heat-brake tube and create a seal. On newer printers that use the AeroStruder (like the Mini 2, Workhorse, and Pro) the zero-sense wire is attached to the COLD end of the extruder (not the heater-block) and this means filament can act as an insulator if there’s a leak in the heat-brake. This isn’t the case with your printer.

The nozzle tip does need to be clean. You can use the red scouring pad to give it a scrub (heat it up first so the filament is soft). Any filament stuck to the nozzle tip will act as an insulator and cause the bed leveling probe to fail.