Hello all. I recently purchased a used Lulzbot Taz 6. I also purchased the M175 V2 head, since I predominantly use 1.75 filament. I have a macbook, and since Lulzbot Cura on Mac doesn’t directly support the M175 head I installed the M175 package using the pdf on their Cura page.

After that I installed the M175 head with the adaptor and powered on the machine. Then, using Cura and the firmware I got from the M175 package install, I updated the firmware manually. I corrected my E-steps using the values I’d recorded, and told the printer to home. The x and y axis homed correctly, but then the printer head/nozzle moved over to begin homing z and nearly crashed into the table. I had to power the machine off to prevent it from slamming into the 3D printed piece holding the z-home button.

I’m not really sure where to go from here. I’ve done a bunch of searching but haven’t found anyone who’s had this issue. Very possible I’ve missed an obvious issue. Please let me know if I can clarify anything, not sure if its a software issue or what. Thanks so much.

Did you select the M175 tool head from the LCD panel on the TAZ 6?

It is likely that the instructions provided gave you the M175v1 information rather than the v2 information. The start gcode and likely the firmware are both incorrect for the v2 and are likely the source of your issue.

Latest taz 6 universal firmware

latest taz 6 M175v2 start gcode

Thank you! I do believe that that is the case. Ended up adding Windows 10 to my Mac so that I could get the Windows version of Lulzbot Cura, which has the above in it, and that seems to have solved things. Thanks!

Having same issue as Cwiggins it seems. Software was fully updated a couple weeks ago on Taz 6 to Marlin 2.0.9.0.13 and Cura 4.13.16. Been working fine with stock extruder. Spent 2 hours trying to figure this out and an instance I thought was certain the printer was going to start breaking things. Never knew a bed/Y framework could deflect that much! Felt like it was deflected down an inch but maybe not that much. There actually might damage but on quick inspection nothing stands out. It seems my solution is going to have to be manually moving the Y axis. Just hate to hate to move the bed when I want to change back to a 2.85 head because that’s what I print 90% of the time.

Did you select the M175v2 from the toolhead menu on the printer?

On the printer, I selected the M175v2. Also did the same on Cura. I am wondering if the adapter plate is throwing it off but the thickness of the plate doesn’t account for the offset. I would estimate the Y axis is 14-15mm (just over 1/2") too far forward towards the user side. The head might be about 3-4mm to far to left on the X as well but I don’t know where it was before the head change so maybe no change there.

Wasn’t there a M175v2.1? I remember something about an upgrade kit as well.

I think the V2 and the V2.1 had slightly different nozzle offsets.

Could be and I had considered this. Although it gives no option on the list pull down list on Marlin or Cura. Just M175v2. In the end, I just had to move the bed. Not ideal at all but sometimes you need to just make it happen. It is working now but after this short foray into printing a little bit of 1.75 I will have to move it back. I have a second printer so I can hold off on the change as long as possible at least.

As a side note, a big thanks to all you guys here. I have often just lurked and used these forums to troubleshoot but never replied or created an account. B-Morgan, your posts have came up a lot and been helpful. Same to you Wrathernaut.

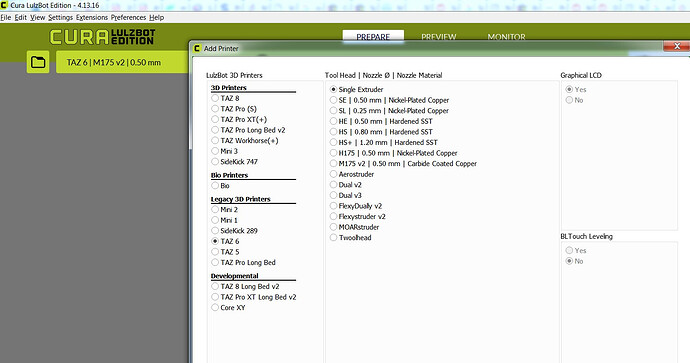

Screenshot of Cura options. Pretty sure H175 isn’t what I want.

I agree that there is only one choice in CuraLE but, if I remember correctly, there was something about the that only being for the 2.1 version.

I believe you can tell which version of the toolhead you have from the markings on the fan shroud as shown below:

1 Like

There was offset differences between M175 and M175v2. IIRC, 2.1 is just changes in the duct. M175v2 put the nozzle in the same relative position as the Titan Aero-based extruders (SE, SL, HE, etc.).

@Silentelk you can put your nozzle offset adjustments into an M206 command. There used to be M206 commands in the toolhead change macros accessed in the menu:

The M206 commands don’t appear to be in there anymore (neither is the Single Extruder for that matter):

Since all supported machine/nozzle combinations are in the same position now, there’s no need for the M206 commands in the shared code used for the toolhead menu.

The Taz 6, being a legacy printer now, isn’t officially supported, so putting M206 in is up to us.

1 Like

Interesting. What file to get to the one you have shown? I have looked through a bunch of the Gcode files but nothing appears to show what you there. My understanding is the solution (for me at least) would be to change MAIN_MENU_ITEM_3_GCODE from "M92E409\nM409\nM206Y0\ to nM206X-14Y4 Am I correct? This would reorient the home position for the printers back about 14mm. That would reorient just that printer head (m175) location (assuming I just modified the file under Taz 6 file) whenever that tool was selected?

I know just enough to be dangerous but not enough to really have a clue haha. To an extent I understand Gcode but I have haven’t to modified it quite this way. 20 years ago I used to program a large 5 router with a 10 ft x 5 ft x 3.5 ft envelope. Was a fun job for 10 months until the company went out of business. Mainly A/B axis changed (wandered slightly) become the machine had 2 degree’s of play. Whenever the machine plan changed machining planes I would insert a stop and then calibrate the newest offset and incorporate it so it would all line up to previous surfaces. But that was 20 years ago and I didn’t change the parameters of the machine or software other than search and edit. And that was 20 years ago…

This is part of the code that gets compiled into the firmware. You could recompile it to do that, but if that’s your only change, it’s not worth the effort.

Just put the M206 corrections into the startup GCODE in CuraLE.

Uncomment by removing the semicolon from the start of the line, then put your M206 corrections in.

Comment out the “reset” M206 command by adding a semicolon at the beginning of the line.