I have a 2019 Taz 6 with the standard extruder (v2.1 I think) with the 0.5mm nozzle. I plan to make some large prints and want to change the nozzle to a larger size. Available nozzles sizes are .6mm, .8mm, 1.0mm and 1.2mm. I’d like to use the largest if possible. Are there any performance issues with any of these increased sizes?

Larger nozzle sizes put an extra demand on the heater block to melt the filament. I’m not sure the stock TAZ 6 Single Extruder heater will be able to handle the largest of the sizes you mentioned.

See the descriptions on https://lulzbot.com/store/tool-heads for the HS and HS+ tool heads.

Thank you for the reply. I figured that it might become a heater block issue. Point well taken. I wonder if there are others here that have experience with larger diameter nozzles on their Taz 6 single extruder tool heads.

I went the other way. I have Single Extruder V2.1 with 0.2 and 0.35 nozzles.

I got the HS+ tool head. The volcano block really lays it down… but really it’s only good for certain parts… and for that it’s a really pricey experiment.

If you want to do the nozzle swap I would suggest at minimum picking up the moarstruder hexagon hot end bits and printing the moarstruder… or buy an assembled tool head with the larger block

Larger nozzles have more propensity for oozing, and can be an issue with trying to level. You may need to manually tweak the temperatures of the filament with regards to soften, wipe, and probe temperatures so that you don’t get plastic in the way. I had issues with stock temps with PLA with a .8mm nozzle on the single extruder, but dialing back the heat about 10 degrees made the difference.

I tried 0.8 ( just drilled out an old worn nozzle). It worked fine with layers up to 0.5, same speeds as default

I have tried 1.2, 1 and .8 on my Taz 6.

All of them are possible but the 1.2 really required heavy tuning of the speeds etc. - i don’t think it was worth it.

I finally settled on the .8 and at a .6 layer height it is really pretty good . Just have to up the nozzle temp a bit and keep the speeds standard (60 and less for wall etc.) Still get great prints from that nozzle on lower layer height too.

Thank you all for responding. Good to hear about the .8mm working well with the std Taz 6 tool head. @Wrathernaut, duly noted about the temp mod suggestions regarding oozing.

Hi, I just bought a second hand Lulzbot taz 6 printer, it is setted for 2.85 filament and has mounted a 0.5 mm nozzle what I have to do if I want to print with an higher diameter nozzle upon 1.2mm let’s say 2mm? Any suggestion?

Big nozzle guy here. I regular push the limits of these machines using the stock tool heads and larger nozzles and have found a regular SE tool head with a Bondtech 1.8mm CHT nozzle works perfectly. I run a gutted Taz Pro XT with an SKR 3 EZ board and Klipper but there is no reason what I am describing would not work on a Taz 6 with the SE tool head and adapter plate. Cap the flow to 20 mm/s/3 in the slicer though. 2mm retraction, and I don’t get any stringing. Increase filament temp about 10-15 degrees.

The HS/HS+ tool heads take Volcano nozzles and those max out at 1.2mm I think.

The extreme option is to get Slice’s 2.4mm nozzle, but that only comes in regular V6 size and the SE tool head will not get hot enough for it. For that you would need the pricey Asteroid tool head, which I have personally confirmed works with that nozzle. But I never got good prints off it, the extrusion is so thick it just collapses on itself.

Do no attempt to use a volcano nozzle adapter and a 1.8 or 2.4 nozzle in an HS/HS+ tool head. The adapters are designed for 1.75 filament only. Ask me how I know.

tl;dr 1.8mm CHT is the max you can expect to print

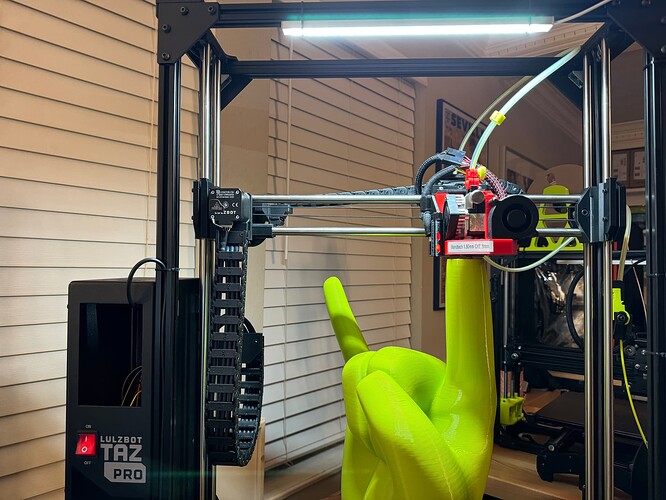

Here is a 1.80 nozzle printing in an SE stock toolhead. The only change was the nozzle.

Thanks Zenotec thanks for your answer. Do you know what tool head mount the TAZ 6? In the photo attached the machine I am getting, could you tell what tool head is on? If you recognize it do you think I can use the 1.8mm bondtech nozzle? Otherwise I will follow your suggestion and I will buy the SE tool head.

Regards

My experience with the Single Extruder tool head is that it can’t maintain temperature with the part cooling fan on. This is my experience with several different ones I have used over the years - three so far. Once the fan comes on, the large heatblock just can’t stay at anything above 200.

I would recommend the SE tool head, with an E3D heat sock. They are not super cheap, but I would look for a used one if you can. People are moving to the Meteor heads lately and eBay will have them from time to time.

Then you would need the Taz 6 adapter plate. And of course a 1.80 CHT V6 bondtech nozzle.

This is my experience, and recommendation. My advice would be to get more opinions from others if possible, I am just one idiot on the Internet.

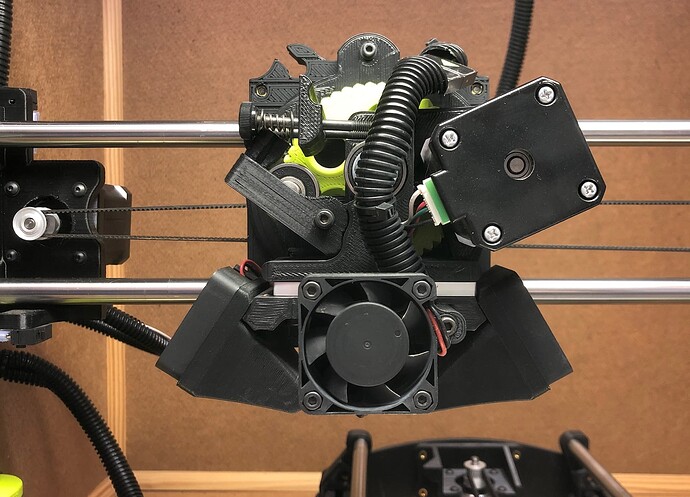

This is likely a modified Taz 6 Single Extruder (not to be confused with the SE). Without seeing the hot end, it’s not possible to know if it’s the Single Extruder or the Moarstruder (or possibly a hot-end swap to a V6 or something else). This toolhead has modifications - visibly a larger heatbreak fan, and a heatsink on the extruder motor. If there are other modifications, we can’t see them - but the factory parts (except for the gear) were printed in black from the factory, not in the green seen here, so this could be almost entirely a custom unit, or just a reprint.

Another notable change is the print bed swapped from a PEI sheet on glass to a powdercoated spring steel surface.

The Single Extruder was designed around printing ABS, so part cooling is pretty bad if you plan on doing PLA, and what part cooling there is is poorly aimed, which can, as zenotek said, cool the nozzle, causing inconsistent extrusion at best, or the printing erroring out due to the inability to keep temperature.

If you don’t have a supply of 2.85mm filament sitting around, I’d recommend skipping the SE toolhead and go with a high-flow 1.75mm toolhead instead. M175v2 if you want something off the shelf, or a self-built Orbiter + Phaetus UHF type unit would be great.

ok thanks again Zenotek, what you think of the option suggested by Wrathernaut? “a high-flow 1.75mm toolhead instead. M175v2”?

thanks Wrathernaut for giving an eye to the printer, eventually as soon I receive the printer and before taking a final decision I will post a photo of the hotend. Anyway you suggest to go for a M175v2 but sAs I said I want to print with at list a 1.8 mm nozzle the 175 will not be feasible isn’it?Anyway the filament I am using for the work I want to do comes from abroad.someone told me to print with a 1 mm nozzle and set the width to 1.8. I would like a simple, economic solution. already the tool heads suggested are more expensive of the printer I bought but will be fine if I get an easy to work head that fit my needs, I am not an expert so I will not go for customized solutions . I hope what I say in broken english is understendable. ![]()

M175 tool head will help in many ways - get out of 2.85mm filament , you gain a powerful Slice Mosquito hot end, a great Bondtech Extruder and you can easily swap out nozzles … from 0.2 on up to 1.8mm Just add the Universal Adapter.

1.75 is just the size going in. You can fill an opening bigger than the source filament just fine once there’s a surface on the other end providing a little backpressure.

A 1.8mm nozzle would be used for making lines of about 2.5mm or more. You can’t make lines smaller than your nozzle opening, and you can’t make lines wider than the width of the nozzle.

There’s a bunch of options here, all I believe in the mid to high price range.

And then there’s the experimental, lower cost option. What could be attempted is to first wrap the heater block in fiberglass cloth and silicone/kapton tape to improve heat retention and then to use a CHT nozzle in 1.0, 1.4 or 1.8 in size. You’ll have to tune it quite a bit but it could work reasonably well.

My attempts to wrap the heater block have not gone too well, it’s just hard to get it around the unusual shape and thick wires. I have succeeded but it looks pretty ugly and blocks some of the part cooling airflow.

Tool head replacements are going to exceed the total practical cost/value of that printer so it’s going to be up to you if that is worth it to you.

Thanks so much for your support Wrathernaut! Now is more clear the all thing. I also read that usually you could push the same nozzle to print a 20% wider. Ciao